Comparing Thermocouple Mounting Styles: Bayonet, Melt Bolt, Clamp & More

When it comes to thermocouples, performance doesn’t just depend on what’s inside – how it’s mounted makes a big difference too. Whether you’re dealing with a tight nozzle on an injection molding machine or retrofitting sensors on an automotive line, the mounting style can make or break your setup. Here’s a quick breakdown of some of the most common mounting styles and how to decide which one fits your application best.

Style Comparison Chart

Mounting Style | Best For | Pros | Considerations |

|---|---|---|---|

| Bayonet | Injection molding, tooling | Easy install, adjustable length, reusable | May loosen in high vibration if not secured |

| Melt Bolt | Extruders, plastic processing | Accurate, high-temp rated, direct melt stream contact | Fixed install, not typically reusable |

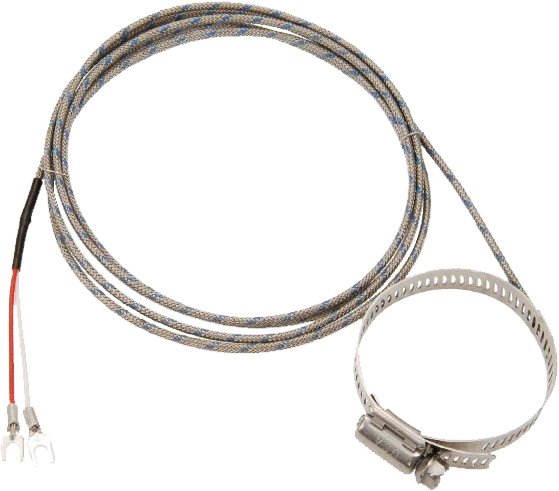

| Clamp-On | Pipe surfaces, retrofits, temporary setups | Non-invasive, easy to move, quick to deploy | Less accurate than immersion, must ensure good contact |

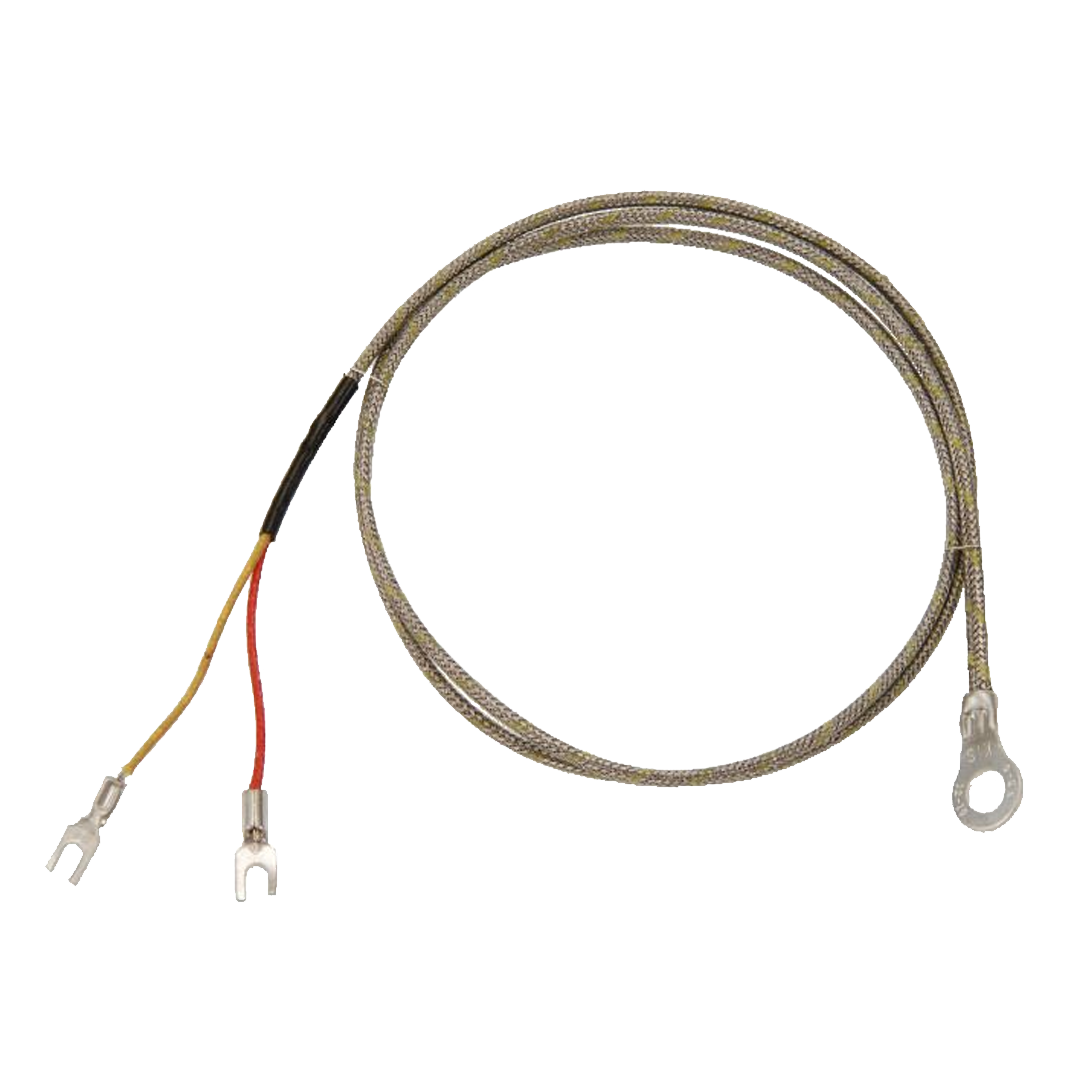

| Nozzle/Ring Lug | Tight spaces, surface mounting | Low-profile, easy to retrofit | Limited to moderate temps, not for immersion |

| Adjustable Probes | Flexible installs, varied depths | Adaptable during install | May not hold calibration as well over time as fixed |

| Fixed-Length Probes | Repeatable installs, long-term reliability | Consistent readings, simple to spec once installed | Requires precise measurement before ordering |

Which One’s Right for You?

Start by thinking about:

• Temperature and process media

• Whether you need immersion or surface sensing

• Installation flexibility or permanence

• Environmental concerns like vibration, washdown, or chemical exposure

Case in Point:

When an automotive supplier faced a supply chain crunch, they needed a quick-turn, custom RTD with precision temperature control to stay on schedule. Tempco delivered a made-to-order solution that fit perfectly into their existing system – proof that mounting and sensor style go hand in hand when downtime isn’t an option. See the full story ›

Choosing the right mounting style isn’t just a detail – it’s a decision that affects installation time, maintenance ease, and the accuracy of every reading. If you’re still unsure, our team is here to help match the sensor to the setup so you can get it right the first time.

Explore Specs & Sensor Styles

Not sure which configuration fits your process? Check out our downloadable mounting style guide or explore product pages for more info:

- Adjustable Bayonet Thermocouples ›

- Melt Bolt Sensors ›

- Clamp-On Options ›

- Ring Lug Thermocouples ›

- And More ›

Weighing The Options

Bayonet Thermocouples: Quick and Adjustable

These are the go-to option for plastics processing, especially in injection molding. Bayonet styles feature a spring-loaded tip and can be installed with bayonet adapters that make adjustments simple. If you need something that’s easy to remove, reposition, or fine-tune after install, this one’s for you.

Pros:

-

Easy to adjust on-site

-

Flexible installation angles

-

Standardized for tooling setups

Cons:

-

Can loosen with heavy vibration if not secured properly

Clamp-On Thermocouples: Surface Sensing Made Simple

For monitoring pipe or surface temperature, clamp-on thermocouples get the job done without the need to drill or tap. These are ideal when you don’t want to disturb your process line or when you need portability between machines.

Pros:

-

Non-invasive install

-

Reusable and movable

-

Ideal for retrofits or temporary use

Cons:

-

May not read as accurately as immersion sensors

-

Sensor contact with the surface must be tightly secured for consistent readings

Melt Bolt Thermocouples: Built for Harsh Plastics Environments

Designed specifically for injection molding and extrusion, melt bolts measure temperature right at the plastic melt stream. They come in both adjustable and fixed-depth styles and can withstand serious heat. If your goal is accuracy in a challenging environment, melt bolts are a solid choice.

Pros:

-

Direct, accurate temperature reading from the melt

-

Rated for high temperatures (up to 1400°F without Teflon®)

-

Designed for permanent installation

Cons:

-

Requires precise placement during installation

-

Not typically reusable once removed

Nozzle & Ring Lug Styles: Small Space Specialists

In small spaces like nozzle tips or die assemblies, compact sensor styles like ring lugs or nozzle probes shine. They attach directly to existing fasteners or recesses to keep things tidy and efficient.

Pros:

• Low profile

• Fits into tight or confined locations

• Easy to integrate with existing hardware

Cons:

• May not read as accurately as immersion sensors

• Sensor contact with the surface must be tightly secured for consistent readings