Click or tap image to expand

Shroud Systems

Refine Results

(11 filters)Shroud Designs

No options available for this section based on your selections

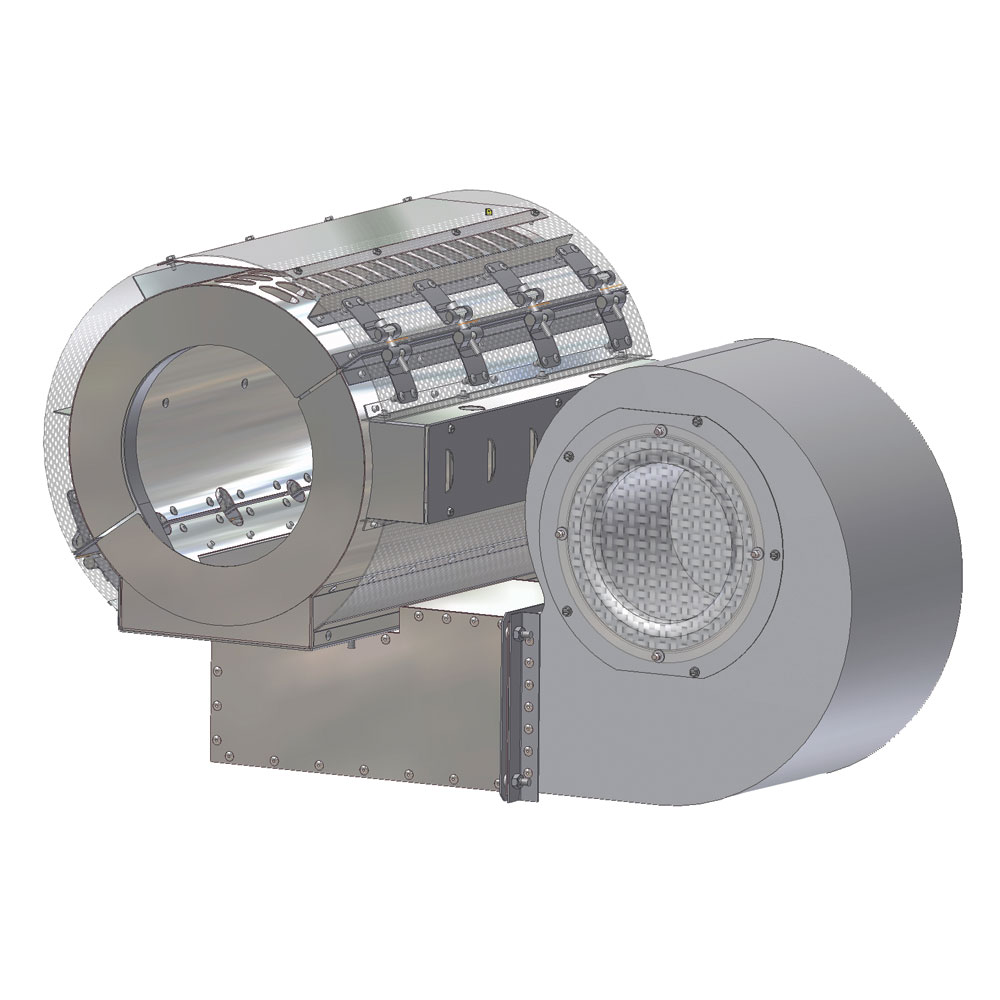

Cool to the Touch

Dual Layer Shroud with Inner Stainless Steel solid layer, a radiation shield that directs the cooling air flow over the heater and an Outer Stainless Steel perforated layer that isolates hot surfaces from contact (cool touch)

Cool to the Touch

Dual Layer Shroud with Inner Stainless Steel solid layer, a radiation shield that directs the cooling air flow over the heater and an Outer Stainless Steel perforated layer that isolates hot surfaces from contact (cool touch)

Tempco’s Cool to the Touch extruder heat/cool systems are custom engineered to provide optimal heating and cooling while providing personnel safety with a Cool Touch perforated outer layer. These systems are designed with finned cast-in heaters that optimize overall system efficiency. The reflective inner layer of the shroud decreases the heat-up cycle, reducing energy consumption. The “maxi-flow” unrestricted blower port directs inlet air to the hottest part of the casting and distributes it evenly over the entire cross section of the zone.

| Recommended Heater Types | Barrel Diameter Range | Zone Length Range | ||

|---|---|---|---|---|

| Min. | Max. | Min. | Max. | |

| Tempco Finned Cast Aluminum Heaters, Vented Ceramic Band Heaters or Maxiband Heaters |

3″ 76 mm |

16″ 406 mm |

5″ 127mm |

42″ 1067 mm |

Scroll for more

ADDITIONAL RESOURCES

Multiversal

Single Layer Shroud Solid Stainless Steel Layer, a radiation shield that directs the cooling air flow over the heater

Multiversal

Single Layer Shroud Solid Stainless Steel Layer, a radiation shield that directs the cooling air flow over the heater

Tempco’s Multi-Versal extruder heat/cool systems are designed for efficient heating and cooling. The shroud systems can be used with many styles of band heaters. Due to the single layer design, the Multi-Versal shroud system has a low profile OD. The reflective interior of the shroud decreases the heat-up cycle, reducing energy consumption. The unrestricted blower port directs inlet air to the hottest part of the heater and distributes it evenly over the entire cross section of the zone.

| Recommended Heater Types | Barrel Diameter Range | Zone Length Range | ||

|---|---|---|---|---|

| Min. | Max. | Min. | Max. | |

| Tempco Finned Cast Aluminum Heaters, Vented Ceramic Band or Maxiband Heaters |

3″ 76 mm |

16″ 406 mm |

3-3/4″ 95 mm |

42″ 1067 mm |

Scroll for more

ADDITIONAL RESOURCES

Arctic Cast

Single Layer Shroud Vented 1/4″ thick Cast Aluminum layer – directs the cooling air flow over the heater

Arctic Cast

Single Layer Shroud Vented 1/4″ thick Cast Aluminum layer – directs the cooling air flow over the heater

Tempco’s Arctic Cast Shroud System was our pioneer shroud design for the air-cooling of extruders. The cooling efficiency of the Arctic Cast shroud system meets or exceeds that of water-cooled systems when used with our field proven high-capacity blowers. The Arctic Cast shroud features a vented 1/4″ thick cast aluminum layer for durability. The cast-in heaters are designed with a large fin surface area to maximize cooling efficiency. The blower port directs inlet air to the hottest part of the heater, distributing it evenly over the entire cross section of the zone.

| Recommended Heater Types | Barrel Diameter Range | Zone Length Range | ||

|---|---|---|---|---|

| Min. | Max. | Min. | Max. | |

| Tempco Finned Cast Aluminum Heaters | 4″ 102 mm | 16″ 406 mm | 6-1/2″ 165 mm | 30-1/2″ 775 mm |

Scroll for more

ADDITIONAL RESOURCES

Mounting Styles

No options available for this section based on your selections

Hinge with Barrel Clamps

Shroud is hinged on one side and secured with clamps on the other; designed for ease of installation. NOTE: Not available on Cast Aluminum Shrouds.

Hinge with Barrel Clamps

Shroud is hinged on one side and secured with clamps on the other; designed for ease of installation. NOTE: Not available on Cast Aluminum Shrouds.

Two Individual Halves

Two-Piece – used where installation space is tight or mounting is difficult Barrel Clamps are used in sheet metal designs Bolts are used in cast aluminum designs

Two Individual Halves

Two-Piece – used where installation space is tight or mounting is difficult Barrel Clamps are used in sheet metal designs Bolts are used in cast aluminum designs

Heater Support

No options available for this section based on your selections

Internal Support Straps

On blower mount half of shroud permits shroud to be opened for servicing without removing unit from barrel

Internal Support Straps

On blower mount half of shroud permits shroud to be opened for servicing without removing unit from barrel

Support U-Bolt

On blower mount half of shroud permits shroud to be opened for servicing without removing unit from barrel. NOTE: Not available on Cast Aluminum Shrouds.

Support U-Bolt

On blower mount half of shroud permits shroud to be opened for servicing without removing unit from barrel. NOTE: Not available on Cast Aluminum Shrouds.

Anti-Rotate Tabs

Used only with Finned Cast-In Heaters to prevent shroud from radial and axial movement around the barrel – Tabs are cast as part of the heater (may require a Terminal Box) NOTE: Not available on Cast Aluminum Shrouds.

Anti-Rotate Tabs

Used only with Finned Cast-In Heaters to prevent shroud from radial and axial movement around the barrel – Tabs are cast as part of the heater (may require a Terminal Box) NOTE: Not available on Cast Aluminum Shrouds.

Blowers

No options available for this section based on your selections

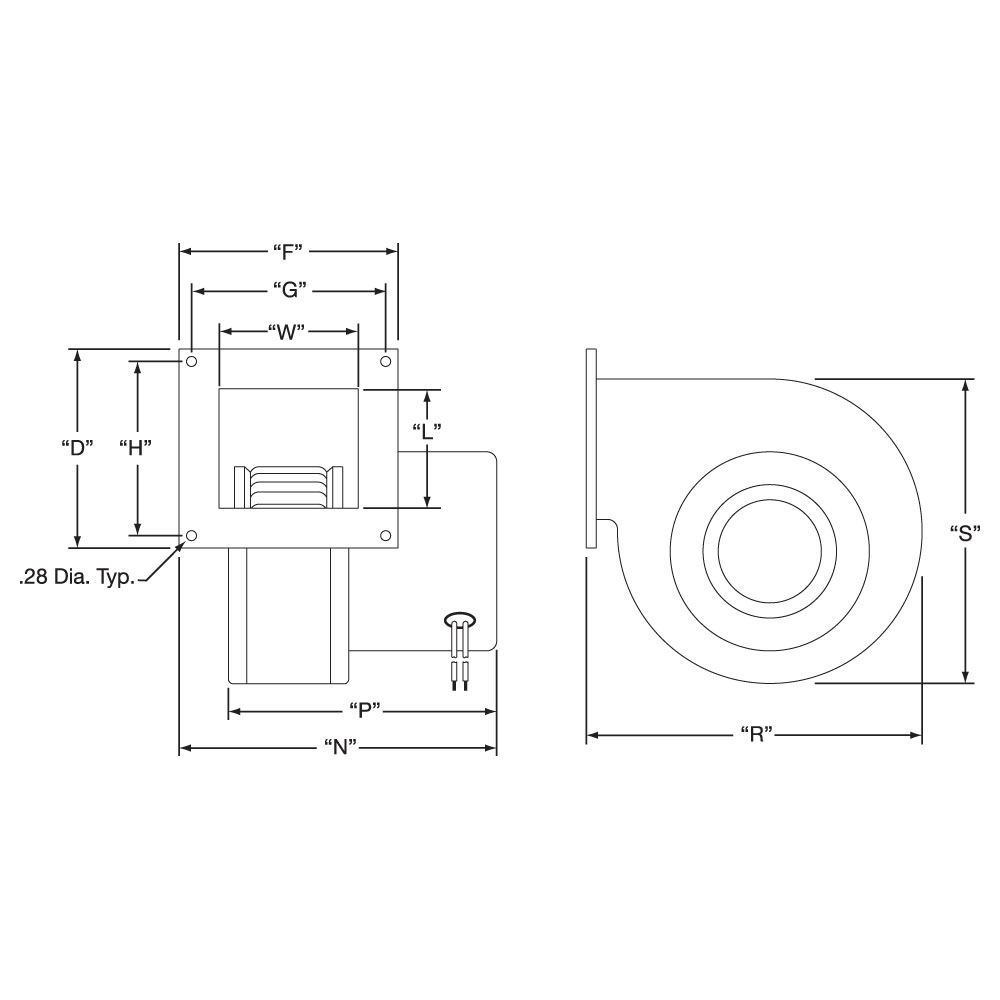

Standard Single Phase Centrifugal Blowers

Tempco standard blowers feature corrosion protected sheet metal housings and impeller wheels. The quiet operation and quick response coupled with high volume unrestricted output results in a field-proven efficient cooling means for extrusion processes. Standard blowers are readily available for single phase 115V or 230V and represent the shortest delivery times.

Standard Single Phase Centrifugal Blowers

Tempco standard blowers feature corrosion protected sheet metal housings and impeller wheels. The quiet operation and quick response coupled with high volume unrestricted output results in a field-proven efficient cooling means for extrusion processes. Standard blowers are readily available for single phase 115V or 230V and represent the shortest delivery times.

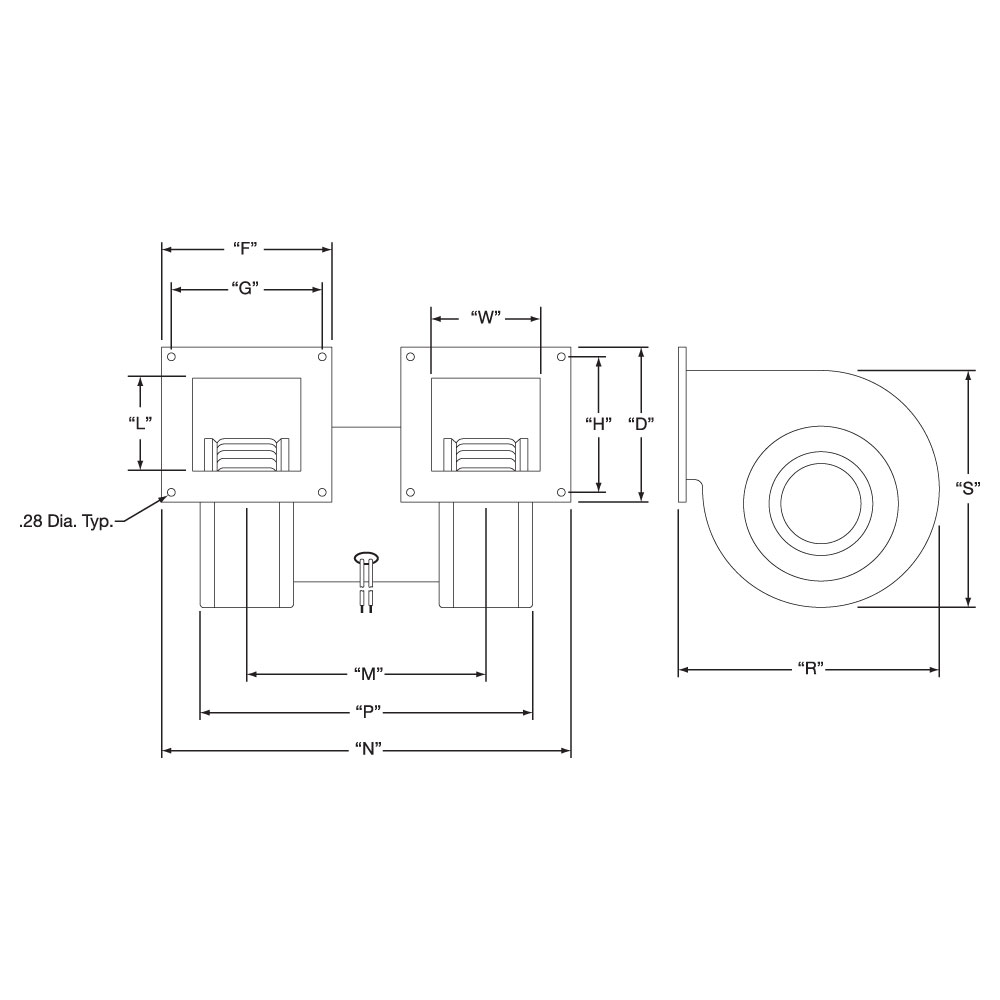

Low-Profile Single Phase Centrifugal Blowers

Tempco low-profile 115/230V single phase blowers offer a narrower footprint than the standard blowers. The motor is integrated with the impeller so that the motor housing protrudes only slightly from the blower housing. Low-profile blowers are made of die-cast aluminum and galvanized sheet steel and are perfect for applications where space is a concern.

Low-Profile Single Phase Centrifugal Blowers

Tempco low-profile 115/230V single phase blowers offer a narrower footprint than the standard blowers. The motor is integrated with the impeller so that the motor housing protrudes only slightly from the blower housing. Low-profile blowers are made of die-cast aluminum and galvanized sheet steel and are perfect for applications where space is a concern.

Universal Three-Phase Centrifugal Blowers

Tempco high-end blowers use heavy duty construction for a long service life. They are available with universal three-phase motors for 50/60 HZ operation on voltages from 202 up to 530V. They meet Cenelec standards and are IP41 or IP54 rated with class B or F insulation systems. These low noise, continuous duty rated blowers operate efficiently under higher static pressure loads than our standard blowers.

Universal Three-Phase Centrifugal Blowers

Tempco high-end blowers use heavy duty construction for a long service life. They are available with universal three-phase motors for 50/60 HZ operation on voltages from 202 up to 530V. They meet Cenelec standards and are IP41 or IP54 rated with class B or F insulation systems. These low noise, continuous duty rated blowers operate efficiently under higher static pressure loads than our standard blowers.

Optional attachments are available for transferring high temperature air up to 200-300° C and inlet filters for dusty environments.

Blower Extensions

Blower extensions are available for applications where space restrictions do not allow the blower to be mounted directly to the shroud assembly.

Blower Extensions

Blower extensions are available for applications where space restrictions do not allow the blower to be mounted directly to the shroud assembly.

Horizontal Blower Extension allows blower to be mounted perpendicular to the shroud. A baffle inside the blower extension smoothly guides air flow into the shroud.

Vertical Blower Extension allows blower to be vertically offset at a distance below the shroud as specified by the customer. Especially useful in retrofit applications.

Vertical Blower Extension with 90° adapter plate allows blower to be vertically offset from the shroud. Blower can be rotated at 90° intervals relative to the extension.

Inlet Guard

Available for Single Inlet Centrifugal Blowers

Blower Locations

No options available for this section based on your selections

Horizontal Blower

Blower is located at 90° or 270° NOTE: Not available on Cast Aluminum Shrouds.

Horizontal Blower

Blower is located at 90° or 270° NOTE: Not available on Cast Aluminum Shrouds.

Vertical Blower

Blower is located at 180° Arctic Cast Shroud Systems: Vertical Orientation is located at the bottom of the shroud; Custom location achieved only by rotating entire shroud system

Vertical Blower

Blower is located at 180° Arctic Cast Shroud Systems: Vertical Orientation is located at the bottom of the shroud; Custom location achieved only by rotating entire shroud system

Custom Location Blower

Blower is positioned per special customer specifications. NOTE: Not available on Cast Aluminum Shrouds.

Custom Location Blower

Blower is positioned per special customer specifications. NOTE: Not available on Cast Aluminum Shrouds.

Air Outlet and Inlet

No options available for this section based on your selections

Combined Air Outlet and Terminal Box (screened)

Standard: Air Outlet combined with Terminal Box at top

Combined Air Outlet and Terminal Box (screened)

Standard: Air Outlet combined with Terminal Box at top

Separate Air Outlet

Optional: Separate top Air Outlet Screened Air Outlet is standard on Multi-Versal Designs NOTE: Not available on Cast Aluminum Shrouds.

Separate Air Outlet

Optional: Separate top Air Outlet Screened Air Outlet is standard on Multi-Versal Designs NOTE: Not available on Cast Aluminum Shrouds.

Air Outlet Shield

Deflects air flow out of shroud and shields shroud from external solid contamination NOTE: Not Available on Multi-Versal Designs or Cast Aluminum Shrouds.

Air Outlet Shield

Deflects air flow out of shroud and shields shroud from external solid contamination NOTE: Not Available on Multi-Versal Designs or Cast Aluminum Shrouds.

Custom Air Outlet Location

Alternate Radial Air Outlet locations available. NOTE: Not available on Cast Aluminum Shrouds.

Custom Air Outlet Location

Alternate Radial Air Outlet locations available. NOTE: Not available on Cast Aluminum Shrouds.

Vent Holes

Heated Air Exhaust holes. NOTE: Not available on Cast Aluminum Shrouds.

Heater Types

No options available for this section based on your selections

Finned Cast Aluminum Heater

Cast Aluminum heater is the standard heater in Tempco shroud system designs with a standard 1/4″ gap between heater halves. Bolt and nut clamping used in cast aluminum shroud designs

Finned Cast Aluminum Heater

Cast Aluminum heater is the standard heater in Tempco shroud system designs with a standard 1/4″ gap between heater halves. Bolt and nut clamping used in cast aluminum shroud designs

Vented Ceramic Band Heater

Thisvented heater was developed to provide another means of heating and cooling high temperature extrusion processes. To reduce the cost and weight of typical shroud systems, Tempco developed a low mass, non-thermally insulated ceramic band heater to work in tandem with a highly efficient stainless steel sheet metal shroud for high temperature heating and cooling extrusion processes. Forced air blowers are used for cooling. The ambient airflow enters the shroud, circulates around the ceramic heater and barrel, removes the heat from the heater and the process and exits the shroud opposite the entrance port. NOTE: Not available on Cast Aluminum Shrouds.

Vented Ceramic Band Heater

Thisvented heater was developed to provide another means of heating and cooling high temperature extrusion processes. To reduce the cost and weight of typical shroud systems, Tempco developed a low mass, non-thermally insulated ceramic band heater to work in tandem with a highly efficient stainless steel sheet metal shroud for high temperature heating and cooling extrusion processes. Forced air blowers are used for cooling. The ambient airflow enters the shroud, circulates around the ceramic heater and barrel, removes the heat from the heater and the process and exits the shroud opposite the entrance port. NOTE: Not available on Cast Aluminum Shrouds.

Maxiband Heater

The channels in the extruded aluminum track are precisely sized to accept a .315 diameter tubular heating element and provide an excellent heat sink for rapid heat transfer and good temperature uniformity. NOTE: Not available on Cast Aluminum Shrouds.

Maxiband Heater

The channels in the extruded aluminum track are precisely sized to accept a .315 diameter tubular heating element and provide an excellent heat sink for rapid heat transfer and good temperature uniformity. NOTE: Not available on Cast Aluminum Shrouds.

Electrical Terminations

No options available for this section based on your selections

Power Input Terminal Box

Power Input Terminal Box with 7/8″ dia. K.O. for 1/2″ conduit

Power Input Terminal Box

Power Input Terminal Box with 7/8″ dia. K.O. for 1/2″ conduit

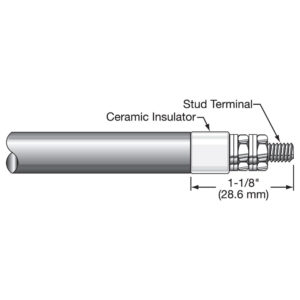

Type T7: Stud Termination with Ceramic Insulator

Ceramic insulator is the same diameter as the heating element. .260″ diameter heater has 6-32 screw terminals. .315″ diameter heater has 8-32 screw terminals. .430″ diameter heater has 10-32 screw terminals.

Type T7: Stud Termination with Ceramic Insulator

Ceramic insulator is the same diameter as the heating element. .260″ diameter heater has 6-32 screw terminals. .315″ diameter heater has 8-32 screw terminals. .430″ diameter heater has 10-32 screw terminals.

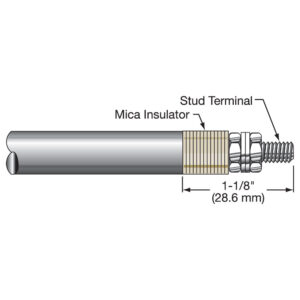

Type T: Stud Termination with Mica Insulator

Mica insulator is the same diameter as the heating element. .260″ diameter heater has 6-32 screw terminals. .315″ diameter heater has 8-32 screw terminals. .430″ diameter heater has 10-32 screw terminals.

Type T: Stud Termination with Mica Insulator

Mica insulator is the same diameter as the heating element. .260″ diameter heater has 6-32 screw terminals. .315″ diameter heater has 8-32 screw terminals. .430″ diameter heater has 10-32 screw terminals.

Termination Options

No options available for this section based on your selections

Louvered Cover

Used when terminal box is separate from air-outlet. NOTE: Not available on Cast Aluminum Shrouds.

Louvered Cover

Used when terminal box is separate from air-outlet. NOTE: Not available on Cast Aluminum Shrouds.

SS Screen

Used when terminal box is combined with air outlet. NOTE: Not available on Cast Aluminum Shrouds.

SS Screen

Used when terminal box is combined with air outlet. NOTE: Not available on Cast Aluminum Shrouds.

Power Input through Blower Mount

Input wiring through knockouts in blower mount eliminates terminal box and facilitates ease of heater service. NOTE: Not available on Cast Aluminum Shrouds.

Power Input through Blower Mount

Input wiring through knockouts in blower mount eliminates terminal box and facilitates ease of heater service. NOTE: Not available on Cast Aluminum Shrouds.

Sensing & Controlling

No options available for this section based on your selections

Existing Zone Control Probe

Shroud System can be designed per customer specifications

Tempco supplied Zone Control Probe

Tempco supplied zone control probe required per customer specifications

Tempco supplied Zone Control Probe

Tempco supplied zone control probe required per customer specifications

Power Control Panel

Tempco customized Power Control Panel designed to complete Your Thermal Loop System required per customer specifications

Power Control Panel

Tempco customized Power Control Panel designed to complete Your Thermal Loop System required per customer specifications