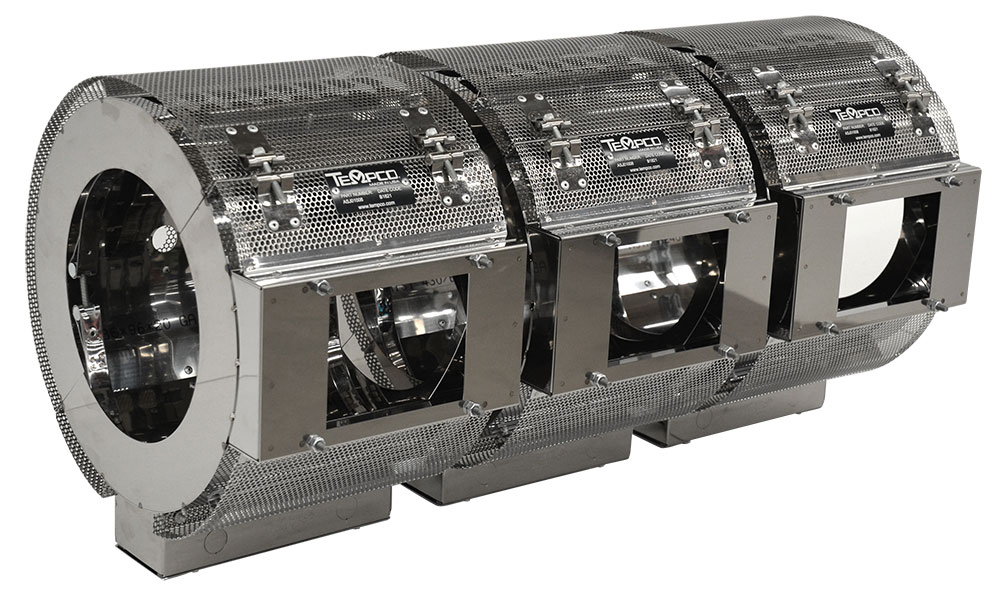

3 Shroud Style Constructions:

- Cool to the Touch dual layer, stainless steel

- Multi-Versal single layer, stainless steel

- Arctic Cast single layer, cast aluminum

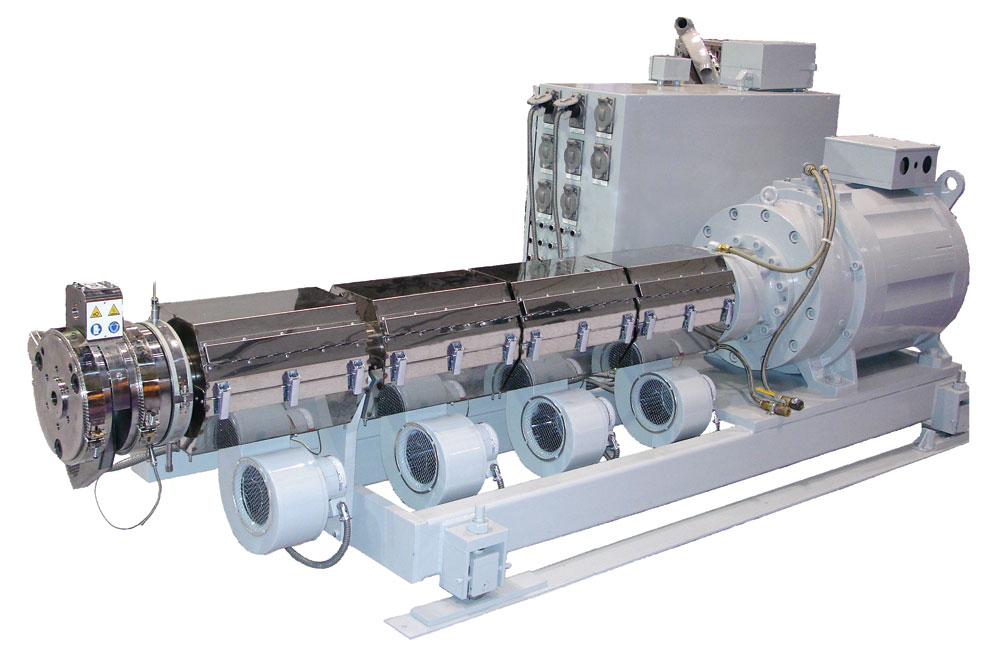

Typical Applications:

- Heating/cooling of extruder barrels

- Injection molding shrouds

Tempco’s Air-Cooled Shroud Systems are highly engineered heating and cooling systems that offer an efficient means to heat and cool the barrels of extruders. These systems are self-contained and can be supplied as ready-to-go, requiring minimum labor and installation cost, and drastically reducing downtime and maintenance upkeep compared to conventional liquid cooling and heating cast-in band heaters.

3 Forced-Air Centrifugal Blowers

- Standard Single Phase

- Low-Profile Single Phase

- Universal Three-Phase

Features and Benefits

Durable Construction

- Stainless steel sheet metal, cast aluminum construction

Easy Installation

- Ready-to-go turnkey system

- Allows for minimum labor and installation cost

Trouble-Free Operating Performance

- Reduced downtime and maintenance compared to conventional liquid-cooled cast-in aluminum band heaters

Highly Efficient Design

- Thermally efficient heating and air cooling through innovative shroud design and optimized direction and ducting of air flow

- Tempco Finned Cast-In Heaters with special high efficiency fins

- Low overall mass cross-section for maximizing thermodynamics

| Shroud Style Construction | Recommended Heater Types | Barrel Diameter Range | Zone Length Range | ||

|---|---|---|---|---|---|

| Minimum | Maximum | Minimum | Maximum | ||

Cool to the Touch™ | Tempco Finned Cast Aluminum Heaters, Vented Ceramic Band or Maxiband Heaters | 3″ 76mm | 23″ 584mm | 5″ 127mm | 42″ 1067mm |

Multi-Versal | Tempco Finned Cast Aluminum Heaters, Vented Ceramic Band or Maxiband Heaters | 3″ 76mm | 23″ 584mm | 3-3/4″ 95mm | 42″ 1067mm |

Arctic Cast® | Tempco Finned Cast Aluminum Heaters | 4″ 102mm | 16″ 406mm | 6-1/2″ 165mm | 30-1/2″ 775mm |

Cool to the Touch Stainless Steel Shrouds

-

Inner Stainless Steel Solid Layer Radiation shield that directs the cooling airflow over the heater and holds in heat to reduce energy use

-

Outer Stainless Steel Perforated Layer Isolates hot surfaces from contact (cool touch) for operator safety

Tempco’s Cool to the Touch extruder heat/cool systems are custom-engineered to provide optimal heating and cooling while providing personnel safety with a cool touch perforated outer layer. These systems are designed with finned cast-in heaters that optimize overall system efficiency.

The reflective inner layer of the shroud decreases the heat-up cycle, reducing energy consumption. The unrestricted blower port directs inlet air to the hottest part of the casting and distributes it evenly over the entire cross-section of the zone.

Multi-Versal Stainless Steel Shrouds

-

Solid Stainless Steel Layer Radiation shield that directs the cooling air flow over the heater and holds in heat to reduce energy use

Tempco’s Multi-Versal extruder heat/cool systems are designed for efficient heating and cooling. A highly adaptable single-layer shroud, they are suited for retrofit and/or new applications regardless of the type of barrel band heater being used. These shroud systems can be used with many styles of band heaters. Due to the single-layer design, the Multi-Versal shroud system has a low profile OD.

The reflective interior of the shroud decreases the heat-up cycle, reducing energy consumption. The unrestricted blower port directs inlet air to the hottest part of the casting and distributes it evenly over the entire cross-section of the zone.

Arctic Cast Extruder Heat/Cool System

- Vented 1/4” thick Cast Aluminum layerDirects the cooling airflow over the heater

This rugged shroud design is recommended for installations where the shroud system could be exposed to physical damage, such as instances where the extruder barrel is low to the ground. It is suited to work with Tempco’s specially designed finned cast-in aluminum heaters and cannot be used on any existing finned cast-in heaters.

The Arctic Cast shroud features a vented 1/4″ thick cast aluminum layer for durability. The cast-in heaters are designed with a large fin surface area to maximize cooling efficiency. The blower port directs inlet air to the hottest part of the heater, distributing it evenly over the entire cross-section of the zone.

Shroud Assembly Features

Stainless Steel

2 Mounting Styles

- Hinge with barrel clamps: designed for ease of installation

- Two individual halves with barrel clamps (Two-Piece): used where installation space is tight or mounting is difficult

- Adjustable clamps upon request

Internal Support Straps or Support U-Bolt on blower mount half of shroud

- Permits shroud to be opened for servicing without removing unit from barrel

Anti-Rotate Tabs

- Used only with Finned Cast-In Heaters to prevent shroud from radial and axial movement around the barrel

- Tabs are cast as part of the heater

Blower Options

- Single or dual Tempco recommended blowers available from 148 CFM up to 1210 CFM at 115V or 230V, or 480V 3-Phase

- Customer-specified blower

- Blower not required for heat-only shrouds

Blower Location

- Horizontal, vertical, or customized options available

- Blower extension housings available

Standard Air Outlet combined with Terminal Box at top

Optional Air Outlet Features

- Air outlet shield deflects air flow out of shroud and shields shroud from external solid contamination

- Air outlet separate from terminal box

- Alternate radial air outlet locations available

Air-Inlet Baffle Optional

Vent Hole(s) Optional

Sensing and Controlling

- Existing zone control probe (shroud system can be designed per customer specifications)

- Tempco supplied zone control probe

- Tempco customized power control panel designed to complete your thermal loop system

Cast Aluminum

Two Individual Halves bolted together (Two-Piece) and clamped around finned cast heater

Blower Options

- Single or dual Tempco recommended blowers available from 148 CFM up to 1210 CFM at 115V or 230V, or 480V 3-Phase

- Customer-specified blower

Blower Location

- Vertical Orientation (at the bottom of the shroud)

- Custom location achieved only by rotating entire shroud system

Standard top Air Outlet

- Custom location achieved only by rotating entire shroud system

Shroud Air-Inlet Baffle with built-in air deflector

- Breaks up incoming airflow, distributing it across the cast-in heater(s)

Sensing and Controlling

- Existing zone control probe (shroud system can be designed per customer specifications)

- Tempco supplied zone control probe

- Tempco customized power control panel designed to complete your thermal loop system

Stainless Steel Shroud Unlatched

Custom Shroud Systems