Engineering Custom Heat Solutions for Aerospace Fueling

A well-known engineering company specializing in space exploration reached out to Tempco with a specific need to regulate the fueling of their spacecraft. They required “Trim Heaters” — process heaters used to purify one of the fuel components during the fueling process. This project involved a collaborative effort between Tempco’s Sales, Engineering, and Production departments to develop an optimal solution.

Design Considerations for the Heaters

Tempco faced several critical parameters when developing the custom heater solution. These considerations included:

- Housing Size

- Overall Length

- Easy Access to Heater Elements

These factors were essential in creating a solution that met the unique requirements of the aerospace application.

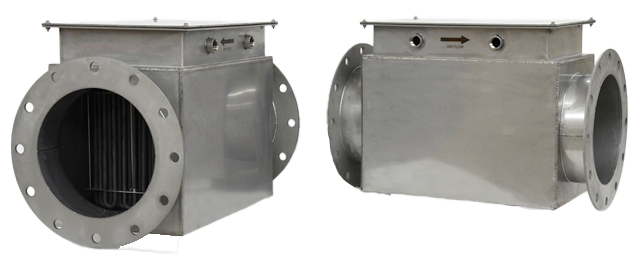

Inline Duct Heaters: The Final Product

The solution involved four different duct heaters, each consisting of tubular heating elements housed within custom enclosures. Key features of the final product include:

- Compact Housing Design

- The heaters were housed in compact units with two different sizes for installation flexibility.

- The housings were constructed using seam-welded stainless steel for durability.

- Flanged for Easy Installation

- Each heater included a flange for secure installation within the system.

- Moisture and Corrosion Resistance

- The terminal housing was rated NEMA 4X, ensuring it is resistant to both moisture and corrosion.

Customization for Field Adjustments

Tempco designed the heaters with flexibility in mind, incorporating several features for in-field adjustments:

- Tubular Heater Insert Packs

- These packs were designed with varying watt densities to allow for fine-tuning and adjustments in the field.

- Custom Heating Elements

- The Incoloy® 840 heating elements were custom-designed in a unique formation, tailored to the specific needs of the aerospace application.

- 3-Phase Power Configuration

- The heating elements were configured in a 3-phase power arrangement for optimal performance.

Temperature Monitoring and Safety Features

Each unit was equipped with a specialized Resistance Temperature Detector (RTD) — a high-limit, mineral-insulated temperature sensor — to ensure precise temperature monitoring and safe operation.

Tempco’s custom inline air duct heaters were designed to meet the rigorous demands of space exploration, providing the necessary heating for the spacecraft fueling process while ensuring durability, flexibility, and safety. This collaborative effort between Tempco and the aerospace company led to the creation of a highly specialized solution tailored to the needs of space technology.