Achieving Precision in Catheter Production with Tempco Band Heaters

When it comes to making medical devices, especially things like thin wall catheters used by cardiologists, getting every detail right is crucial. These catheters help treat heart patients all over the world. But how do original equipment manufacturers (OEMs) ensure that their machines make these important devices with such precision? The secret lies in the technology behind the scenes—including Tempco band heaters and temperature sensors. Recently we worked with an OEM and manufacturer of medical devices who has been in the industry for over 40 years. They produce over 15,000 products used in the medical field such as stents, balloon catheters and guide wires. The custom components that Tempco provides are vital to their medical device production and contribute to saving the lives of over 37 million people.

The Importance of Band Heaters

Why High-Temperature Heaters Are Key

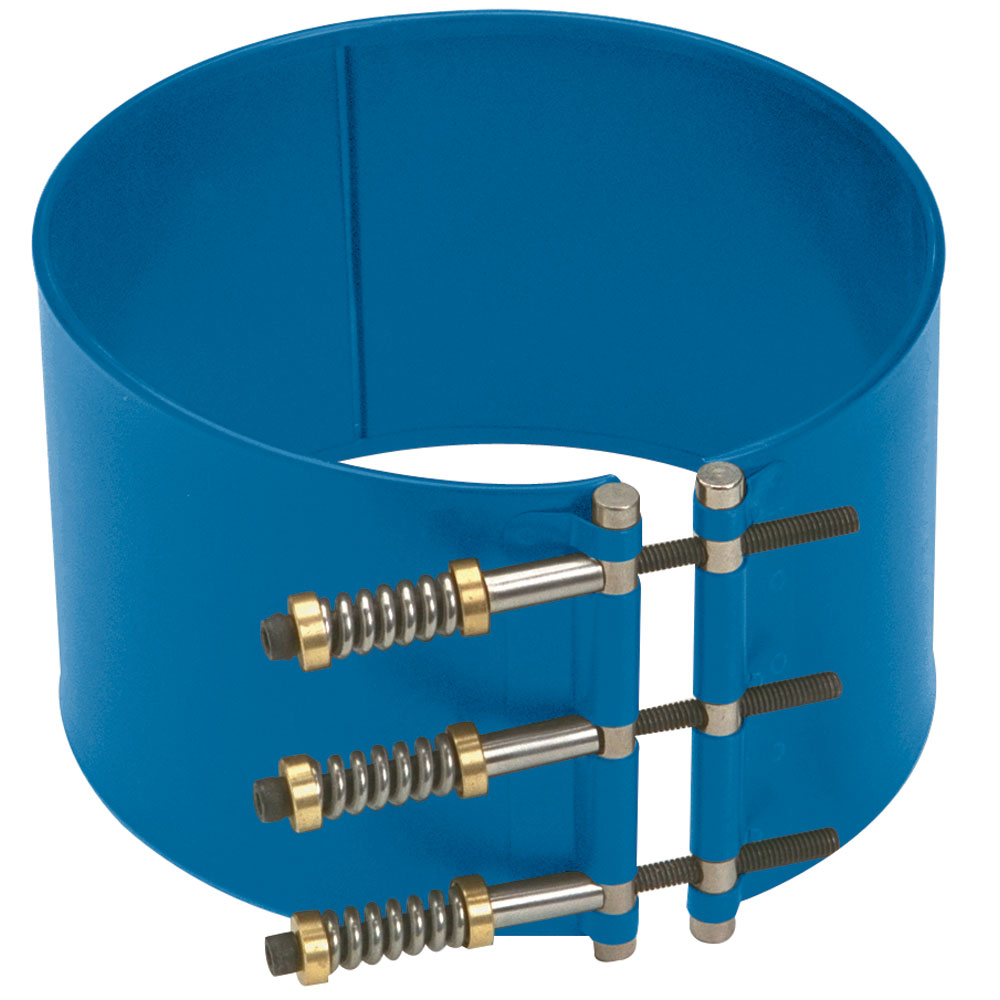

Manufacturing ballon catheters involves melting and molding plastic at high temperatures. This can be as hot as 770°F! To handle these conditions, manufacturers use Tempco Mi-Plus® Band Heaters. These are not just any heaters—they are specially designed to provide excellent thermal conductivity at high temperatures and high watt densities without failure.

How Mi-Plus® Band Heaters Work

Tempco Mi-Plus band heaters wrap around the metal parts, called tooling dies, that shape the plastic into catheters. By keeping the application temperature steady and high, these heaters make sure the plastic melts evenly and flows properly through the dies. This is important because it helps create catheters with precise dimensions. Without this kind of reliable heating, it would be hard to make sure every catheter meets the high standards required for medical use.

The Role of Temperature Sensors

Why Sensors Are So Important

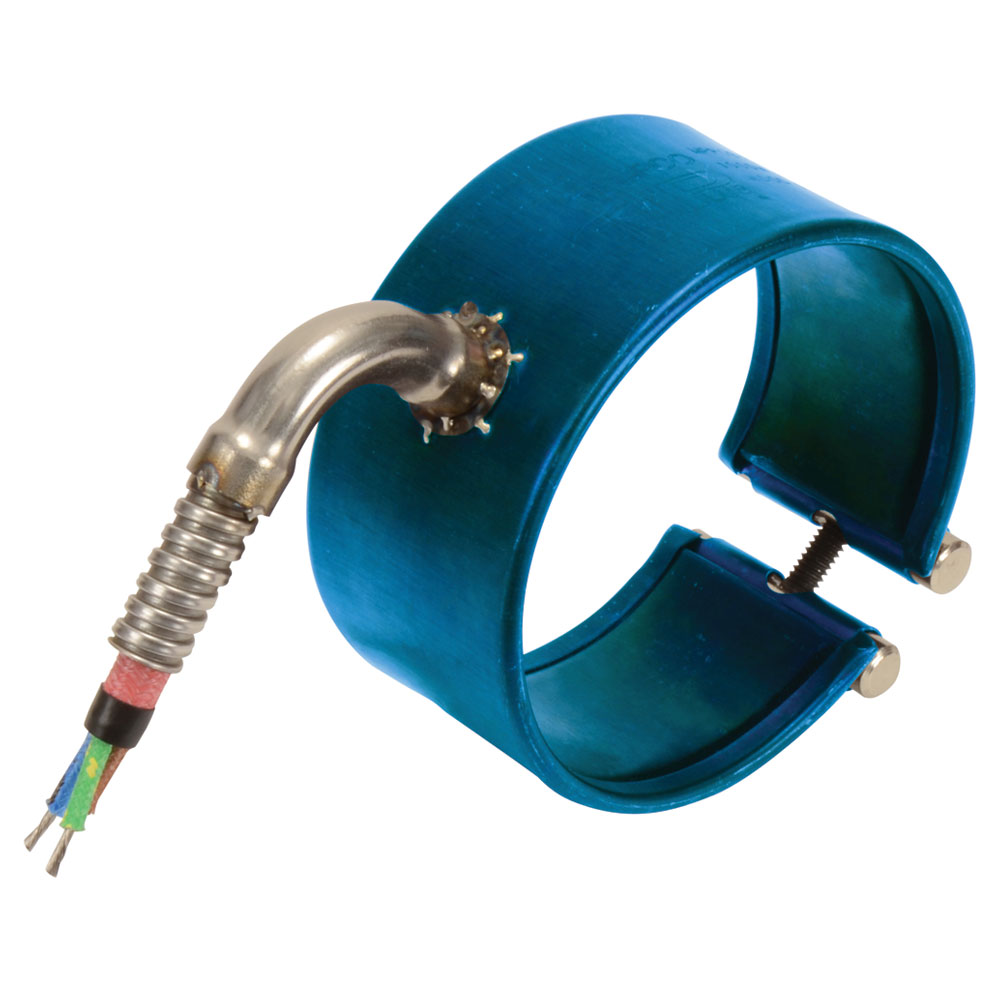

Besides heating, precise temperature control is another big part of making sure medical devices are high quality. That’s where Tempco temperature sensors come in. This manufacturer utilizes our Mineral Insulated Thermocouple Assemblies that are designed to measure temperatures very accurately. They have a rigid design for adverse conditions and high temperatures.

How Tempco Temperature Sensors Help

The thermocouple assemblies are connected to Programmable Logic Controllers (PLCs), which are systems that automatically adjust the temperature. These sensors help keep everything running smoothly by providing real-time temperature readings. If the temperature starts to drift, the PLCs can make quick adjustments to keep things on track. This kind of precise control helps ensure that the catheters are made to the exact specifications needed, which is crucial for their effectiveness and safety.

Custom Components for Better Manufacturing

Why Custom Parts Matter

Not every medical device is the same, and that means the equipment used to make them needs to be customized too. Tempco is a leader in creating custom components like band heaters and temperature sensors that are tailored to fit specific needs. This customization ensures that the manufacturing process is as efficient and accurate as possible.

Example of Custom Features

For example, Tempco can design our mineral insulated band heaters to fit the specific shapes of the tooling dies used in catheter production. This includes non-standard gap sizes and custom clamping, as well as slots, cut-outs and holes to accommodate extruder barrel specifications. We also offer a wide range of electrical terminations with features such as high temperature ratings, abrasion resistant materials and right-angle leads.

Sensors can also be customized for different manufacturing processes. Calibration type, Type K or Type J being the most common, and sensor construction are carefully selected based on application requirements. This level of detail helps improve both the efficiency and accuracy of making medical devices.

How Tempco’s Technology Helps Patients

The Connection Between Precision and Patient Care

The precise heat and accurate temperature readings provided by Tempco band heaters and thermocouples don’t just make the manufacturing process smoother–it has a direct impact on patient care. Balloon catheters are critical for treating conditions like peripheral artery disease. Making sure these catheters are manufactured accurately helps reduce complications and makes treatments more effective.

Success on a Global Scale

The manufacturer produces over three million balloon catheters every year, which is more than any other company in the world. This impressive number is possible, in part, because of the reliable performance of Tempco’s components. The catheters produced help improve the lives of millions of people, highlighting the crucial role of high-quality band heaters and sensors in medical manufacturing.

Why Tempco’s Solutions Matter for Manufacturers

Tempco band heaters and temperature sensors are essential to the medical device manufacturing process. Our high-temperature heaters ensure that plastic is melted evenly, while our temperature sensors communicate accurate temperature readings to PLCs. This combination helps produce balloon catheters that meet strict medical standards, improving manufacturing efficiency and patient care. For anyone involved in making medical devices, Tempco’s technology offers a way to achieve high precision and quality. By providing custom solutions tailored to specific needs, Tempco helps manufacturers produce life-saving devices that make a real difference in people’s lives. If you’re looking for top-notch components to enhance your manufacturing process, our expertise and innovative products could be just what you need. What problems can Tempco solve for you? Find solutions to your heating needs today: