Tempco cartridge heaters are important components used in many industrial heating applications including injection molding, fluid heating, packaging, food processing, aerospace and medical equipment. People typically use them to heat platens and molds or as liquid immersion heaters. They provide localized heat quickly and efficiently when inserted into drilled holes. Businesses value these cost-effective heaters for their small size, watt density capabilities, efficient heat transfer and custom options.

How Do Cartridge Heaters Work?

Cartridge heaters use resistive heating elements or resistance wire to generate heat. When electricity flows through the heating coil inside the metal sheath, it creates heat. This electrical resistance then transfers as heat to the surrounding material, allowing for quick and efficient heating.

The design of these industrial heaters maximizes contact with the material in your application, which improves thermal efficiency. This means they heat faster and use less energy, which is essential for industrial processes that need precise temperatures.

What Are the Operating Temperatures?

Tempco cartridge heaters can operate at various temperatures. They can reach a maximum temperature of 1200°F with a stainless-steel sheath. With an Incoloy® 800 sheath, they can reach up to 1400°F. This range allows them to work effectively and meet varying heat requirements in different industrial settings, ensuring reliable performance.

For example, in injection molding, maintaining high temperatures consistently is crucial for success. Uniform temperatures help the process run more efficiently, reducing the chances of defects and producing a high-quality product.

Are There Special Features Available?

Yes, Tempco cartridge heaters come with several features that enhance their performance:

- Sheath Material Options –The choice of sheath material affects thermal conductivity, durability, and resistance to chemical exposure. This ensures efficient heat transfer and protects the heater from environmental hazards. Tempco offers a variety of options including 321, 304, 316 S/S, Incoloy® 800. Use oursheath material reference guideto find the right fit.

- Custom Lengths – Tempco offers heaters in different sizes to fit specific machinery or processes perfectly, maximizing efficiency.

- High Watt Density Options –These heaters heat quickly and evenly. This is helpful in high demand situations.

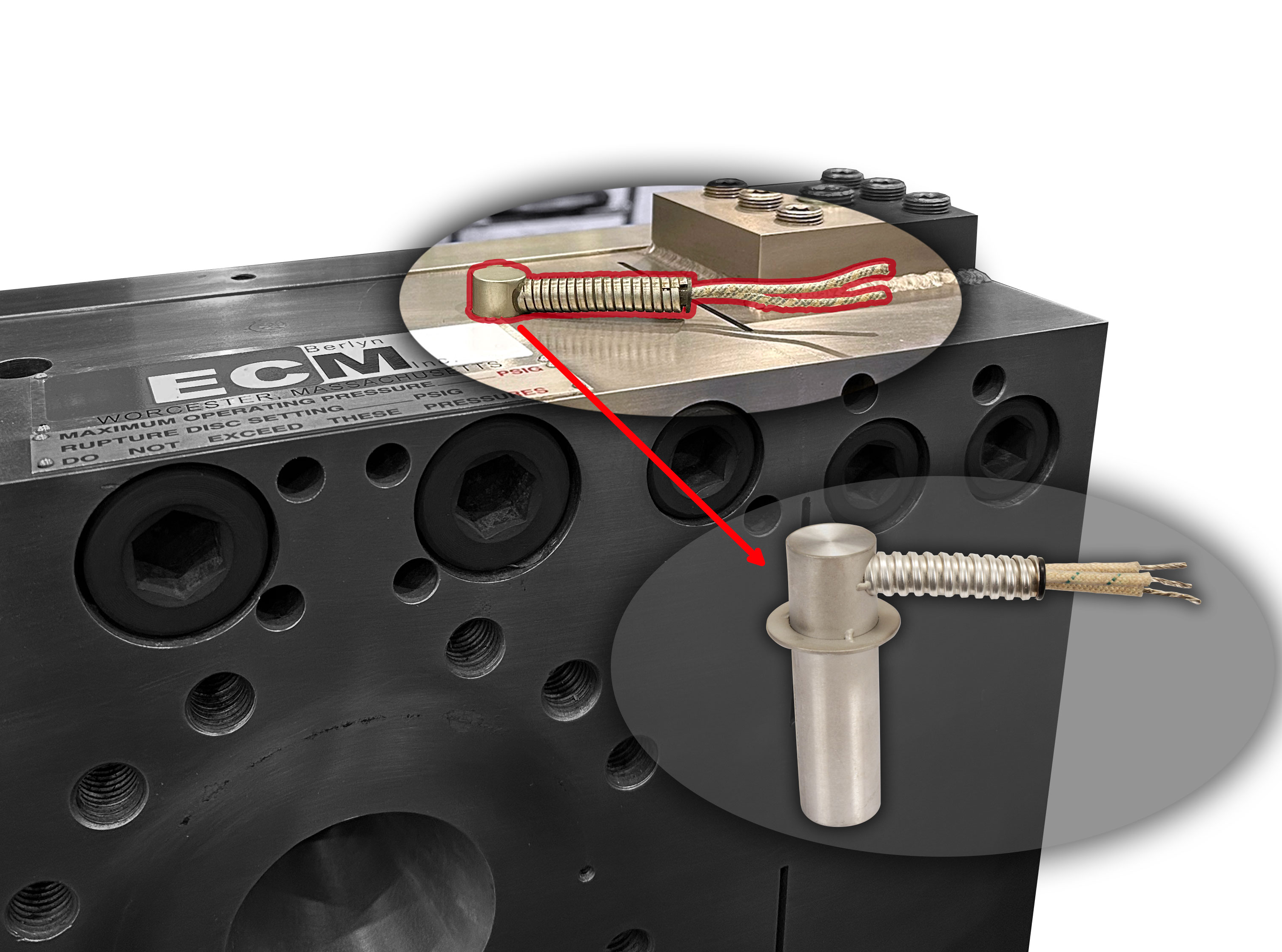

- Temperature Sensors – Adding a sensor to your cartridge heater ensures that you get accurate temperature readings. Choose from thermostats, thermal cut-off fuses, Thermocouples, RTDs, and thermistors.

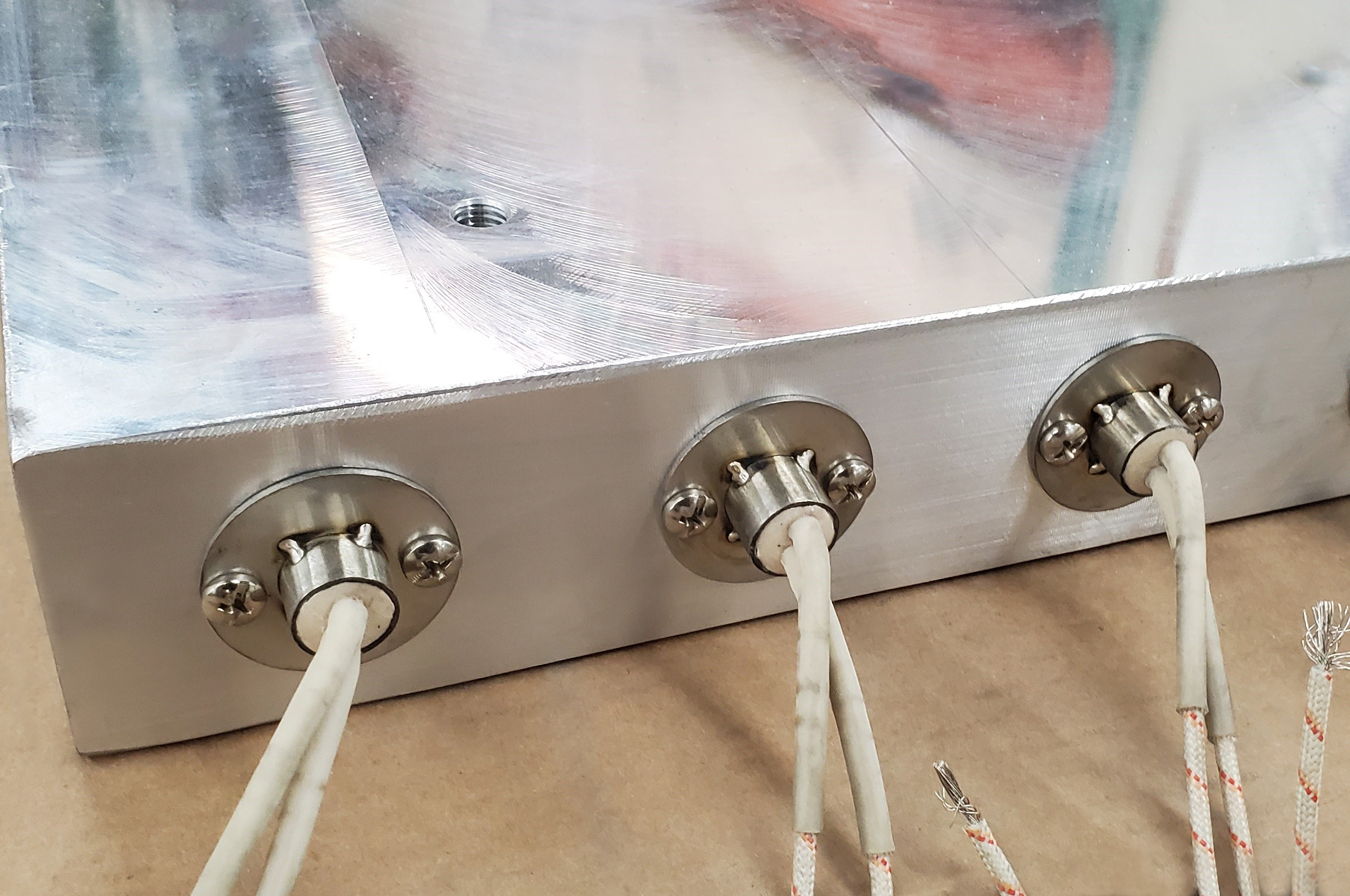

- Wide Variety of Electrical Terminations and Termination Options –Tempco offers over 20 electrical terminations and many termination options to meet your application needs.

- Mounting options –Integrate your heater easier with customized mounting options such as threaded fittings and flanges. This offers flexible installation in unique spaces.

- Custom Options –Tempco offers many other custom options. We can build them to your specifications, so you get exactly the heater you need.

Choosing the right features can significantly improve cartridge heater performance as well as heater life.

How Do I Determine Wattage Density?

Wattage density is important for selecting the right heating element. Calculate the wattage density by dividing the total wattage by the surface area of the heater. This helps engineers understand how much heat the heater produces in a specific area.

Watts/In2 = Wattage/ (Diameter x 3.1416 x Heated Length)

The maximum watt density you should use depends on several factors. These include the material being heated, the operating temperature, the size of the hole, and the heat-up time. Maximum watt densities can reach up to 300 watts/in2.

For more information on how to calculate the wattage density check out our quick guide to watt density calculations. Or, dig into our engineering data guide for expanded information.

For the best results, you should consider the material you need to heat and how quickly it needs to reach a certain temperature.

What’s the Difference in Construction Materials?

The materials used in the construction of cartridge heaters greatly affect their performance. Tempco manufactures low and high density cartridge heaters with a variety of sheath materials.

Low-Density Cartridge Heaters:

LD cartridge heaters use helically wound Nickel-Chrome resistance wire. Our team places evenly stretched wire through a ceramic core. We use high purity Magnesium Oxide (MgO) to fill all remaining space inside the ceramic insulator.

This construction provides high temperature strength, good thermal conductivity and resistance to oxidation.

Hi-Density Cartridge Heaters:

HD cartridge heaters use Nickel-Chrome resistance wire precisely wound around a magnesium oxide core. The heating element is as close to the inside of the sheath as possible, resulting in excellent heat transfer. These heaters go through a swaging process that compacts the MgO insulating material into a solid mass, which improves thermal conductivity.

This construction allows for higher watt densities, higher operating temperatures and longer heater life.

Sheath Material:

While each heater is different, Tempco typically uses stainless steel (SS) and nickel-plated brass.

- 304 Stainless Steel –This material is resistant to corrosion and can withstand high temperatures, making it ideal for tough environments. Its durability ensures a longer lifespan. It is the standard sheath material for Tempco’s Low-Density Cartridge Heaters

- 321 & 316 Stainless Steel –These materials provide improved corrosion resistance over normal 304 stainless steel.

- 321 SS has superior welding properties because of the Titanium in it. This is beneficial for the integrity of the heater end discs and mounting options. It is the standard material for Tempco’s High-Density Cartridge Heaters.

- 316 SS is the preferred sheath material for several industries including Food & Beverage, Medical and Aerospace. It is resistant to salt exposure and corrosion in general because of the Molybdenum content.

- Incoloy® 800 – Allows you to achieve higher operating temperatures (up to 1400° F) while also providing corrosion resistance. It is a high-performance super alloy of Iron-Nickel-Chromium with superior mechanical properties and good resistance to oxidation and high temperature corrosion

Choosing the right materials is crucial for optimal heat transfer and durability, impacting the efficiency of industrial heating.

Where are Cartridge Heaters Used?

Many industries use these heating elements in their heating applications, including:

- Injection Molding –They provide evenly distributed heat to molds, which helps shape plastic efficiently and reduces cycle times.

- Packaging –Heaters warm materials for proper sealing, ensuring quality in packaging.

- Food Processing –They maintain safe cooking and pasteurization temperatures, which is important for food safety.

- Die Heating –These heaters maintain precise temperatures during metal forming processes, which is vital for making quality parts.

- Plastics and Rubber Processing –They heat molds and dies, making operations smoother and more efficient.

- Medical Equipment –Because of their compact size, they are easily integrated into a range of applications from patient comfort to equipment manufacturing.

- Aerospace – They heat critical components and are able to withstand harsh environments.

- Additive Manufacturing –They provide localized heat for both printing nozzles and print beds, melting the material efficiently for the 3D printing process

Knowing these applications helps engineers choose the right heating elements for their specific needs.

How Will Cartridge Heaters Benefit Me?

Using Tempco cartridge heaters provides several advantages:

- Fast Heat-up Times –Rapid heating is essential for efficient processing and reducing downtime in industrial operations.

- Compact Design – Their small size makes it easy to fit them into various machines without occupying too much space.

- Precise Temperature Control: These heaters maintain consistent temperatures with the right temperature sensor and controller, which helps ensure quality in manufacturing and reduces defects.

- Energy Efficiency: Their effective heat transfer minimizes energy use, which is important for keeping operational costs low.

These benefits make cartridge heaters an excellent choice for improving productivity and efficiency in industrial applications.

Tempco cartridge heaters play a crucial role in various industrial heating applications, offering fast, efficient, and precise solutions. Using these electric heating elements, industries can boost productivity and lower costs. This makes them a valuable tool in any industrial setting.

Talk with a heater specialist now, (888) 268-6396, or read more on how to improve the life and maintain cartridge heaters.