Click or tap image to expand

Resistance Wire & Ribbon

- Type A: Wire only 2190°F (1200°C)

- Type C: Wire 2100°F (1150°C) Ribbon 2055°F (1125°C)

- Type D: Wire only 2370°F (1300°C)

Refine Results

(1 filter)Wire Types

No options available for this section based on your selections

Type A Wire (Kanthal Nikothal 80 or Equivalent)

Composition: 80% Nickel, 20% Chromium

Specific Resistance: 655 Ohms / circ. mil foot @ 68°F / 20°C

Maximum continuous operating temperature: 2190°F / 1200°C (element temperature in air)

Melting Point: 1400°C / 2550°F

Density: (lbs/in3): 0.300

Specific Gravity: 8.41

Resistance Tolerance: 8 ga. through 23 ga. ±3%, 24 ga. through 36 ga. ±5%, 37 ga. through 43 ga. ±8%

Type A Wire (Kanthal Nikothal 80 or Equivalent)

Composition: 80% Nickel, 20% Chromium

Specific Resistance: 655 Ohms / circ. mil foot @ 68°F / 20°C

Maximum continuous operating temperature: 2190°F / 1200°C (element temperature in air)

Melting Point: 1400°C / 2550°F

Density: (lbs/in3): 0.300

Specific Gravity: 8.41

Resistance Tolerance: 8 ga. through 23 ga. ±3%, 24 ga. through 36 ga. ±5%, 37 ga. through 43 ga. ±8%

Cross Reference Chart

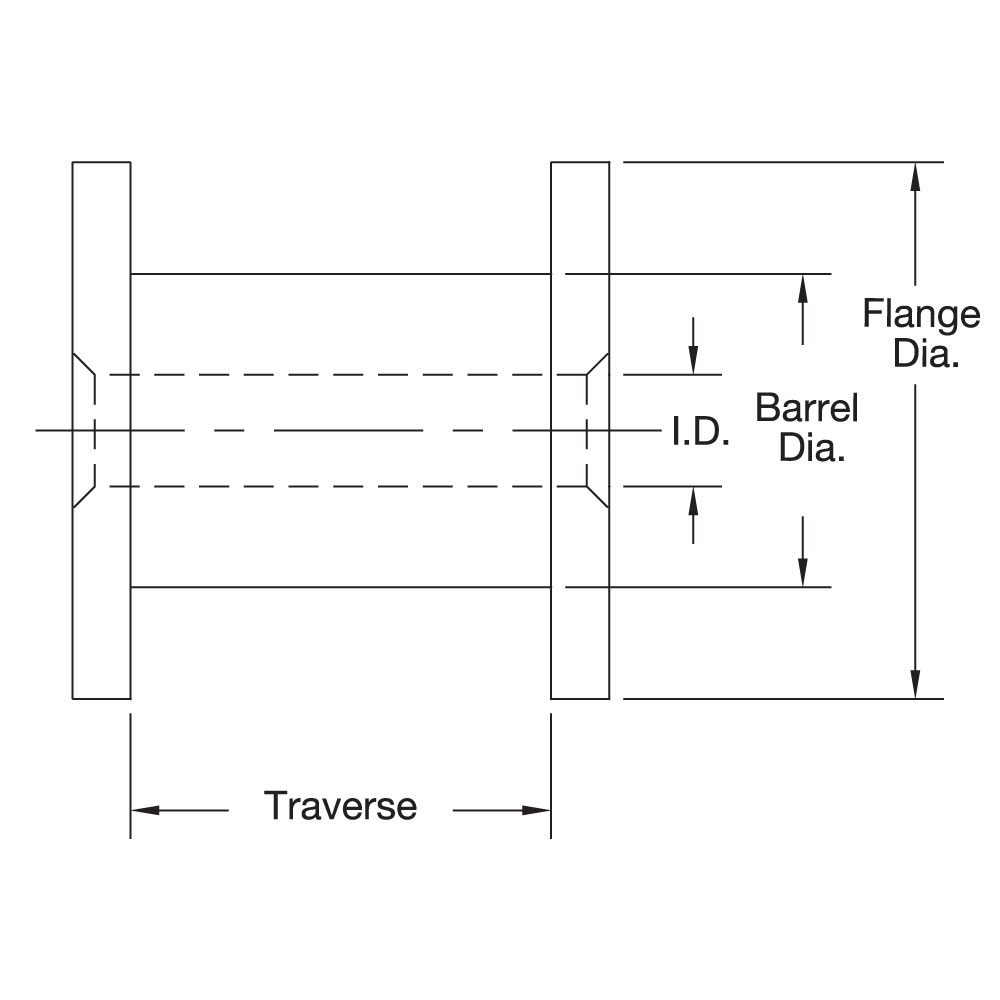

Standard Spool Dimensions

Temperature Chart

| Kanthal | Hoskins | Driver-Harris | Carpenter | Rescal | Calfine Wire | Harrison | Thyssen Krup VDM | MWS Wire | Jelliff | Molecu |

|---|---|---|---|---|---|---|---|---|---|---|

| Nikrothal 60 | Chromel C | Nichrome | Tophet C | Resistohm 60 | Stablohm 675 | HAI-NiCr 60 | Cronifer II | MWS-675 | Alloy C | Electroloy |

| Nikrothal 80 | Chromel A | Nichrome V | Tophet A | Resistohm 80 | Stablohm 650 | Nichrome V | Cronix 80 | MWS-650 | Alloy A | Protoloy |

| Kanthal D | Alloy 815 | — | Alchrome DK | Resistohm 135 | Stablohm 812 | Alferon 901 | Aluchrom 5 | — | — | — |

Scroll for more

| Spool Code | Flange | Barrel | Traverse | Bore ID | ||||

|---|---|---|---|---|---|---|---|---|

| in | mm | in | mm | in | mm | in | mm | |

| A | 2.5 | 63 | 1.75 | 44 | 3 | 76 | 0.62 | 16 |

| B | 3 | 76 | 1.75 | 44 | 3 | 77 | 0.62 | 16 |

| C | 5 | 127 | 3 | 76 | 3.5 | 89 | 0.62 | 16 |

| D | 6 | 152 | 3.5 | 89 | 3.5 | 89 | 0.62 | 16 |

| E | 3.15 | 80 | 2 | 51 | 2.5 | 63 | 0.62 | 16 |

| F | 3.87 | 98 | 2.37 | 59 | 3.12 | 79 | 0.62 | 16 |

| G | 4.92 | 125 | 3.1 | 79 | 3.93 | 100 | 0.62 | 16 |

Scroll for more

| Temp. °F | 68 | 212 | 392 | 752 | 1112 | 1292 | 1472 | 1652 | 1832 | 2012 | 2192 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Temp. °C | 20 | 100 | 200 | 400 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| Factor | 1.00 | 1.01 | 1.02 | 1.04 | 1.05 | 1.04 | 1.04 | 1.04 | 1.05 | 1.05 | 1.06 |

| (These figures are given as a basis for engineering calculations and represent average material as supplied.) | |||||||||||

Scroll for more

Type C Wire (Kanthal Nikrothal 60 or Equivalent)

Composition: 60% Nickel, 16% Chromium, Fe balance

Specific Resistance: 668 Ohms / circ. mil foot @ 68°F / 20°C

Maximum continuous operating temperature: 2100°F / 1150°C (element temperature in air)

Melting Point: 1390°C / 2535°F

Density: (lbs/in3): 0.296

Specific Gravity: 8.25

Resistance Tolerance: 16 ga. through 23 ga. ±3%, 24 ga. through 36 ga. ±5%, 37 ga. through 44 ga. ±8%

Type C Wire (Kanthal Nikrothal 60 or Equivalent)

Composition: 60% Nickel, 16% Chromium, Fe balance

Specific Resistance: 668 Ohms / circ. mil foot @ 68°F / 20°C

Maximum continuous operating temperature: 2100°F / 1150°C (element temperature in air)

Melting Point: 1390°C / 2535°F

Density: (lbs/in3): 0.296

Specific Gravity: 8.25

Resistance Tolerance: 16 ga. through 23 ga. ±3%, 24 ga. through 36 ga. ±5%, 37 ga. through 44 ga. ±8%

Cross Reference Chart

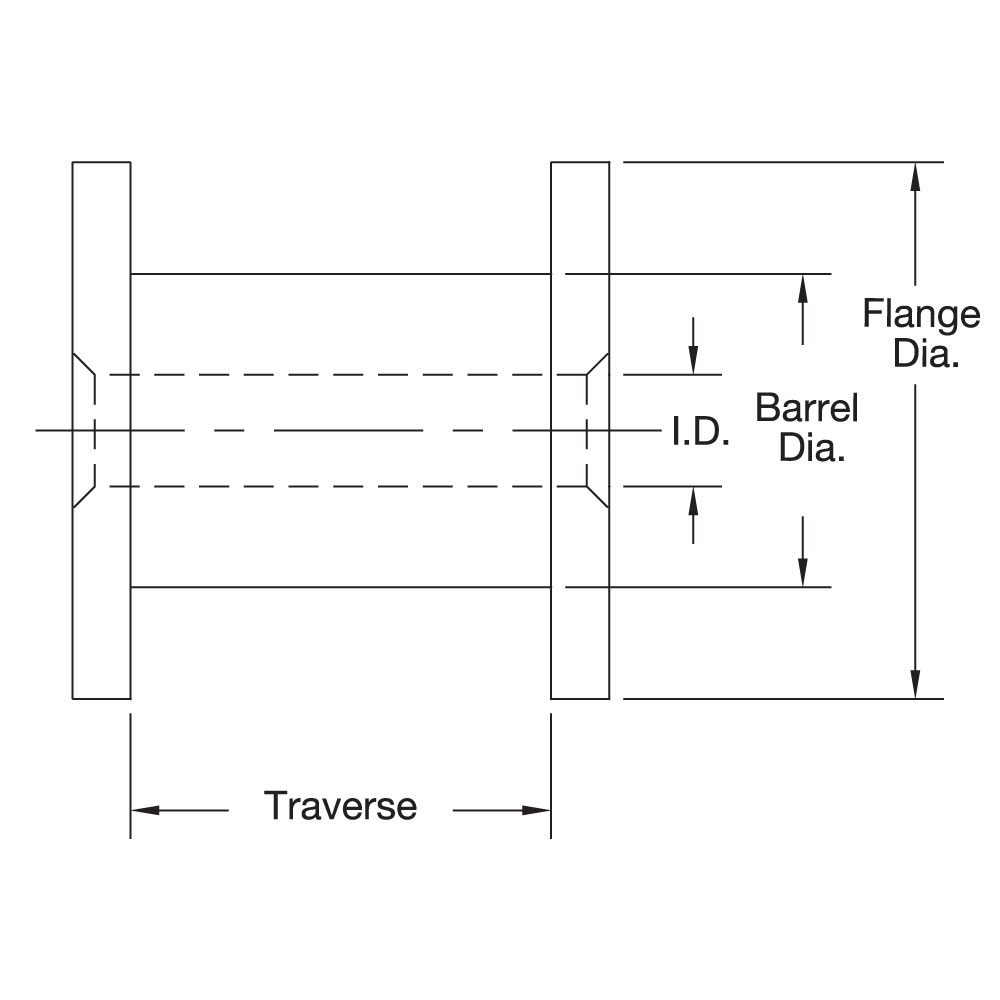

Standard Spool Dimensions

Temperature Chart

| Kanthal | Hoskins | Driver-Harris | Carpenter | Rescal | Calfine Wire | Harrison | Thyssen Krup VDM | MWS Wire | Jelliff | Molecu |

| Nikrothal 60 | Chromel C | Nichrome | Tophet C | Resistohm 60 | Stablohm 675 | HAI-NiCr 60 | Cronifer II | MWS-675 | Alloy C | Electroloy |

| Nikrothal 80 | Chromel A | Nichrome V | Tophet A | Resistohm 80 | Stablohm 650 | Nichrome V | Cronix 80 | MWS-650 | Alloy A | Protoloy |

| Kanthal D | Alloy 815 | — | Alchrome DK | Resistohm 135 | Stablohm 812 | Alferon 901 | Aluchrom 5 | — | — | — |

Scroll for more

| Spool Code | Flange | Barrel | Traverse | Bore ID | ||||

| in | mm | in | mm | in | mm | in | mm | |

| A | 2.5 | 63 | 1.75 | 44 | 3 | 76 | 0.62 | 16 |

| B | 3 | 76 | 1.75 | 44 | 3 | 77 | 0.62 | 16 |

| C | 5 | 127 | 3 | 76 | 3.5 | 89 | 0.62 | 16 |

| D | 6 | 152 | 3.5 | 89 | 3.5 | 89 | 0.62 | 16 |

| E | 3.15 | 80 | 2 | 51 | 2.5 | 63 | 0.62 | 16 |

| F | 3.87 | 98 | 2.37 | 59 | 3.12 | 79 | 0.62 | 16 |

| G | 4.92 | 125 | 3.1 | 79 | 3.93 | 100 | 0.62 | 16 |

Scroll for more

| Temp. °F | 68 | 212 | 392 | 752 | 1112 | 1292 | 1472 | 1652 | 1832 | 2012 | 2192 |

| Temp. °C | 20 | 100 | 200 | 400 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| Factor | 1.00 | 1.02 | 1.04 | 1.06 | 1.09 | 1.09 | 1.10 | 1.10 | 1.11 | 1.12 | 1.13 |

| (These figures are given as a basis for engineering calculations and represent average material as supplied.) | |||||||||||

Scroll for more

Type C Ribbon (Kanthal Nikrothal 60 or Equivalent)

Composition: 60% Nickel, 16% Chromium, Fe balance

Specific Resistance: 524 Ohms / circ. mil foot @ 68°F / 20°C

Maximum continuous operating temperature: 2100°F / 1150°C (element temperature in air)

Melting Point: 1390°C / 2535°F

Density: (lbs/in3): 0.296

Specific Gravity: 8.25

Resistance Tolerance: ±5%

Type C Ribbon (Kanthal Nikrothal 60 or Equivalent)

Composition: 60% Nickel, 16% Chromium, Fe balance

Specific Resistance: 524 Ohms / circ. mil foot @ 68°F / 20°C

Maximum continuous operating temperature: 2100°F / 1150°C (element temperature in air)

Melting Point: 1390°C / 2535°F

Density: (lbs/in3): 0.296

Specific Gravity: 8.25

Resistance Tolerance: ±5%

Cross Reference Chart

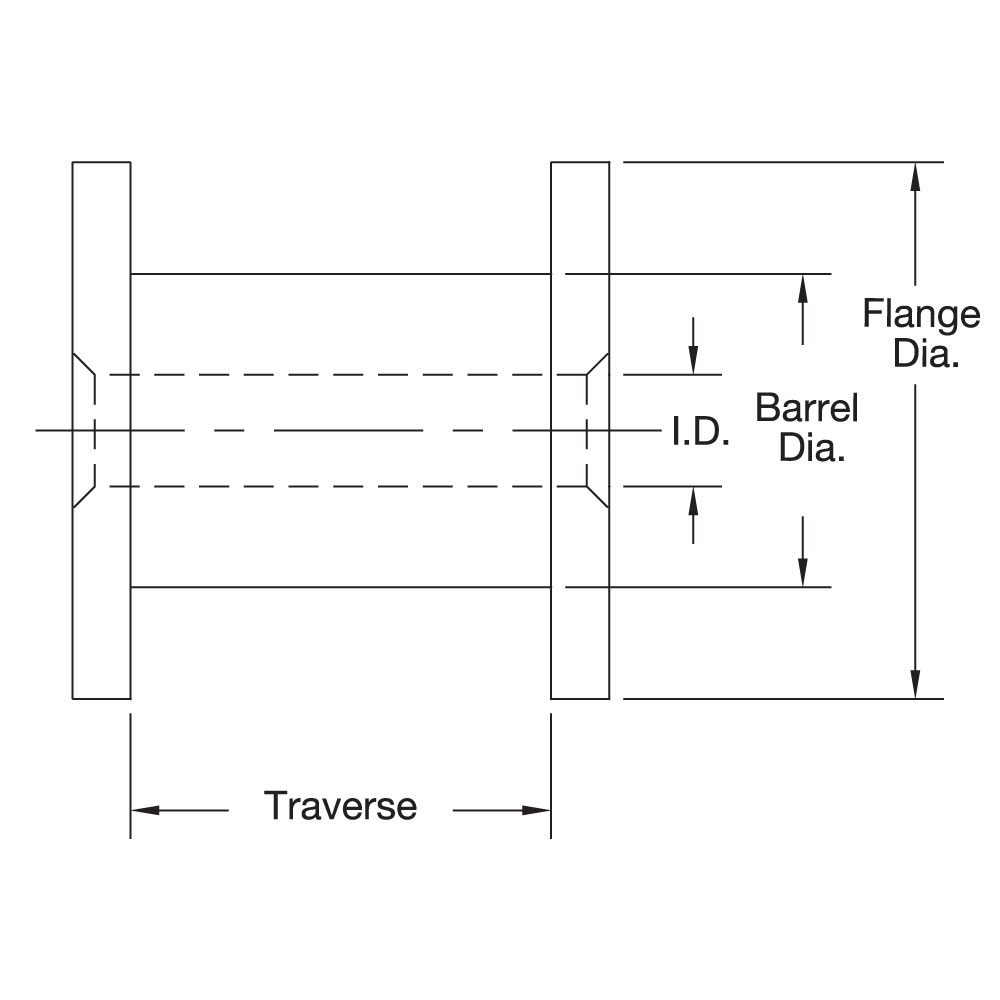

Standard Spool Dimensions

Temperature Chart

| Kanthal | Hoskins | Driver-Harris | Carpenter | Rescal | Calfine Wire | Harrison | Thyssen Krup VDM | MWS Wire | Jelliff | Molecu |

| Nikrothal 60 | Chromel C | Nichrome | Tophet C | Resistohm 60 | Stablohm 675 | HAI-NiCr 60 | Cronifer II | MWS-675 | Alloy C | Electroloy |

| Nikrothal 80 | Chromel A | Nichrome V | Tophet A | Resistohm 80 | Stablohm 650 | Nichrome V | Cronix 80 | MWS-650 | Alloy A | Protoloy |

| Kanthal D | Alloy 815 | — | Alchrome DK | Resistohm 135 | Stablohm 812 | Alferon 901 | Aluchrom 5 | — | — | — |

Scroll for more

| Spool Code | Flange | Barrel | Traverse | Bore ID | ||||

| in | mm | in | mm | in | mm | in | mm | |

| A | 2.5 | 63 | 1.75 | 44 | 3 | 76 | 0.62 | 16 |

| B | 3 | 76 | 1.75 | 44 | 3 | 77 | 0.62 | 16 |

| C | 5 | 127 | 3 | 76 | 3.5 | 89 | 0.62 | 16 |

| D | 6 | 152 | 3.5 | 89 | 3.5 | 89 | 0.62 | 16 |

| E | 3.15 | 80 | 2 | 51 | 2.5 | 63 | 0.62 | 16 |

| F | 3.87 | 98 | 2.37 | 59 | 3.12 | 79 | 0.62 | 16 |

| G | 4.92 | 125 | 3.1 | 79 | 3.93 | 100 | 0.62 | 16 |

Scroll for more

| Temp. °F | 68 | 212 | 392 | 752 | 1112 | 1292 | 1472 | 1652 | 1832 | 2012 | 2192 |

| Temp. °C | 20 | 100 | 200 | 400 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| Factor | 1.00 | 1.02 | 1.04 | 1.06 | 1.09 | 1.09 | 1.10 | 1.10 | 1.11 | 1.12 | 1.13 |

| (These figures are given as a basis for engineering calculations and represent average material as supplied.) | |||||||||||

Scroll for more

Type D Wire (Kanthal Wire or Equivalent)

Composition: 22% Chromium, 4.8% Aluminum, Fe balance

Specific Resistance: 812 Ohms / circ. mil foot @ 68°F / 20°C

Maximum continuous operating temperature: 2370°F / 1300°C (element temperature in air)

Melting Point: 1500°C / 2730°F

Density: (lbs/in3): 0.262

Resistance Tolerance: 17 ga. through 23 ga. ±3%, 24 ga. through 36 ga. ±5%, 37 ga. ±8%

Type D Wire (Kanthal Wire or Equivalent)

Composition: 22% Chromium, 4.8% Aluminum, Fe balance

Specific Resistance: 812 Ohms / circ. mil foot @ 68°F / 20°C

Maximum continuous operating temperature: 2370°F / 1300°C (element temperature in air)

Melting Point: 1500°C / 2730°F

Density: (lbs/in3): 0.262

Resistance Tolerance: 17 ga. through 23 ga. ±3%, 24 ga. through 36 ga. ±5%, 37 ga. ±8%

Cross Reference Chart

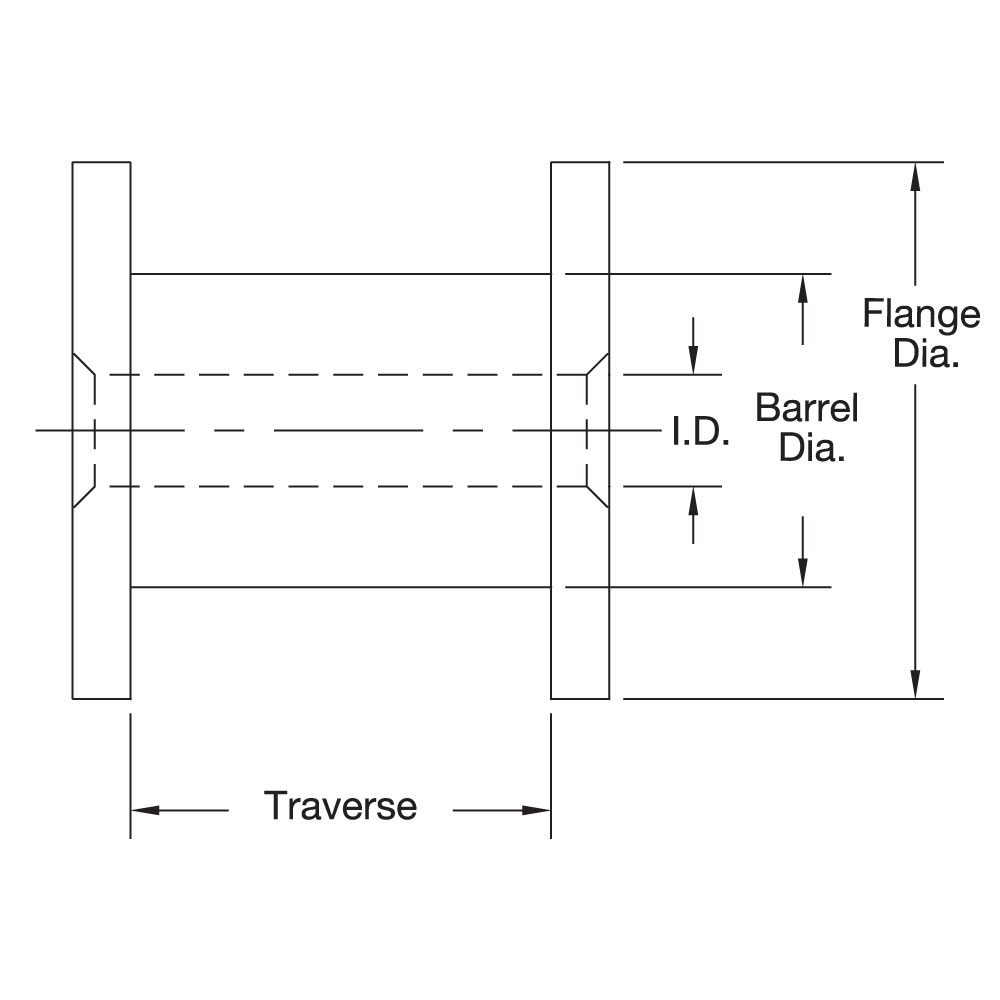

Standard Spool Dimensions

Temperature Chart

| Kanthal | Hoskins | Driver-Harris | Carpenter | Rescal | Calfine Wire | Harrison | Thyssen Krup VDM | MWS Wire | Jelliff | Molecu |

| Nikrothal 60 | Chromel C | Nichrome | Tophet C | Resistohm 60 | Stablohm 675 | HAI-NiCr 60 | Cronifer II | MWS-675 | Alloy C | Electroloy |

| Nikrothal 80 | Chromel A | Nichrome V | Tophet A | Resistohm 80 | Stablohm 650 | Nichrome V | Cronix 80 | MWS-650 | Alloy A | Protoloy |

| Kanthal D | Alloy 815 | — | Alchrome DK | Resistohm 135 | Stablohm 812 | Alferon 901 | Aluchrom 5 | — | — | — |

Scroll for more

| Spool Code | Flange | Barrel | Traverse | Bore ID | ||||

| in | mm | in | mm | in | mm | in | mm | |

| A | 2.5 | 63 | 1.75 | 44 | 3 | 76 | 0.62 | 16 |

| B | 3 | 76 | 1.75 | 44 | 3 | 77 | 0.62 | 16 |

| C | 5 | 127 | 3 | 76 | 3.5 | 89 | 0.62 | 16 |

| D | 6 | 152 | 3.5 | 89 | 3.5 | 89 | 0.62 | 16 |

| E | 3.15 | 80 | 2 | 51 | 2.5 | 63 | 0.62 | 16 |

| F | 3.87 | 98 | 2.37 | 59 | 3.12 | 79 | 0.62 | 16 |

| G | 4.92 | 125 | 3.1 | 79 | 3.93 | 100 | 0.62 | 16 |

Scroll for more

| Temp. °F | 68 | 212 | 392 | 752 | 1112 | 1292 | 1472 | 1652 | 1832 | 2012 | 2192 |

| Temp. °C | 20 | 100 | 200 | 400 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| Factor | 1.00 | 1.00 | 1.01 | 1.02 | 1.04 | 1.05 | 1.06 | 1.07 | 1.07 | 1.07 | 1.08 |

| (These figures are given as a basis for engineering calculations and represent average material as supplied.) | |||||||||||

Scroll for more