Click or tap image to expand

Pressure Rated Flanged Immersion Heaters

Refine Results

(9 filters)Watt Densities for Typical Applications

No options available for this section based on your selections

8 watts/in2 (1.3 watts/cm2)

Typical Applications: Fuel Oils (Bunker C and Number 6)

Recommended Materials

Flange: 150-lb Raised Face Forged Carbon Steel

Elements: Steel Sheath

8 watts/in2 (1.3 watts/cm2)

Typical Applications: Fuel Oils (Bunker C and Number 6)

Recommended Materials

Flange: 150-lb Raised Face Forged Carbon Steel

Elements: Steel Sheath

15 watts/in2 (2.3 watts/cm2)

Typical Applications: Fuel Oils (Number 4&5)

Recommended Materials

Flange: 150-lb Raised Face Forged Carbon Steel

Elements: Steel

15 watts/in2 (2.3 watts/cm2)

Typical Applications: Fuel Oils (Number 4&5)

Recommended Materials

Flange: 150-lb Raised Face Forged Carbon Steel

Elements: Steel

16 watts/in2 (2.5 watts/cm2)

Typical Applications: Heat Transfer Oils ● Liquid Paraffin

Recommended Materials

Flange: 150-lb Raised Face Forged Carbon Steel

Elements: Incoloy® 800 sheath

16 watts/in2 (2.5 watts/cm2)

Typical Applications: Heat Transfer Oils ● Liquid Paraffin

Recommended Materials

Flange: 150-lb Raised Face Forged Carbon Steel

Elements: Incoloy® 800 sheath

23 watts/in2 (3.6 watts/cm2) (A)

Typical Applications: Lightweight Oils ● Heat Transfer Oils ● Degreasing Solutions

Recommended Materials

Flange: 150-lb Raised Face Forged Carbon Steel

Elements: Steel

23 watts/in2 (3.6 watts/cm2) (A)

Typical Applications: Lightweight Oils ● Heat Transfer Oils ● Degreasing Solutions

Recommended Materials

Flange: 150-lb Raised Face Forged Carbon Steel

Elements: Steel

23 watts/in2 (3.6 watts/cm2) (B)

Typical Applications: Forced Air ● Caustic Solutions ● Degreasing Solutions

Recommended Materials

Flange: 150-lb Raised Face Forged Carbon Steel

Elements: Incoloy® 800 Sheath

23 watts/in2 (3.6 watts/cm2) (B)

Typical Applications: Forced Air ● Caustic Solutions ● Degreasing Solutions

Recommended Materials

Flange: 150-lb Raised Face Forged Carbon Steel

Elements: Incoloy® 800 Sheath

48 watts/in2 (7.4 watts/cm2)

Typical Applications: Process Water

Recommended Materials

Flange: 150-lb Raised Face Forged Carbon Steel

Elements: Incoloy® 800 Sheath

48 watts/in2 (7.4 watts/cm2)

Typical Applications: Process Water

Recommended Materials

Flange: 150-lb Raised Face Forged Carbon Steel

Elements: Incoloy® 800 Sheath

60 watts/in2 (9.3 watts/cm2) (A)

Typical Applications: Deionized Water

Recommended Materials

Flange: 150-lb Raised Face 316 Stainless Steel

Elements: 316 Stainless Steel Sheath

60 watts/in2 (9.3 watts/cm2) (A)

Typical Applications: Deionized Water

Recommended Materials

Flange: 150-lb Raised Face 316 Stainless Steel

Elements: 316 Stainless Steel Sheath

60 watts/in2 (9.3 watts/cm2) (B)

Typical Applications: Clean Water

Recommended Materials

Flange: 150-lb Raised Face Forged Carbon Steel

Elements: Copper Sheath

60 watts/in2 (9.3 watts/cm2) (B)

Typical Applications: Clean Water

Recommended Materials

Flange: 150-lb Raised Face Forged Carbon Steel

Elements: Copper Sheath

60 watts/in2 (9.3 watts/cm2) ©

Typical Applications: Deionized Water

Recommended Materials

Flange: 150-lb Raised Face 316 Stainless Steel

Elements: 316 Stainless Steel Sheath

60 watts/in2 (9.3 watts/cm2) ©

Typical Applications: Deionized Water

Recommended Materials

Flange: 150-lb Raised Face 316 Stainless Steel

Elements: 316 Stainless Steel Sheath

Sheath Materials

No options available for this section based on your selections

Incoloy 840

Nickel 18-20%, Chromium 18-22%, Iron balance. Has about 10% less nickel than Incoloy 800. Used in many air heating applications, where it has exhibited superior oxidation resistance at less cost than Incoloy 800.

Incoloy 840

Nickel 18-20%, Chromium 18-22%, Iron balance. Has about 10% less nickel than Incoloy 800. Used in many air heating applications, where it has exhibited superior oxidation resistance at less cost than Incoloy 800.

Incoloy 800

Nickel 30-35%, Chromium 19-23%, Iron balance. The high nickel content of this alloy contributes to its resistance to scaling and corrosion. Used in air heating and immersion heating of potable water and other liquids.

Incoloy 800

Nickel 30-35%, Chromium 19-23%, Iron balance. The high nickel content of this alloy contributes to its resistance to scaling and corrosion. Used in air heating and immersion heating of potable water and other liquids.

316/316L Stainless Steel

Chromium 16-18%, Nickel 11-14%, Iron balance. (316L – Low Carbon) Modified with the addition of Molybdenum (2-3%) to improve corrosion resistance in certain environments, especially those which would tend to cause pitting due to the presence of chlorides. Applications include deionized water. Maximum Sheath Temperature: 1200°F / 649°C

316/316L Stainless Steel

Chromium 16-18%, Nickel 11-14%, Iron balance. (316L – Low Carbon) Modified with the addition of Molybdenum (2-3%) to improve corrosion resistance in certain environments, especially those which would tend to cause pitting due to the presence of chlorides. Applications include deionized water. Maximum Sheath Temperature: 1200°F / 649°C

304/304L Stainless Steel

Chromium 18-20%, Nickel 8-11%, Iron balance. (304L – Low Carbon) Used in the food industry, medical, and chemical heating. Maximum Sheath Temperature: 1200°F (649°C)

304/304L Stainless Steel

Chromium 18-20%, Nickel 8-11%, Iron balance. (304L – Low Carbon) Used in the food industry, medical, and chemical heating. Maximum Sheath Temperature: 1200°F (649°C)

321 Stainless Steel

Chromium 17-20%, Nickel 9-13%, Iron balance. Modified with the addition of Titanium to prevent carbide precipitation and resulting intergranular corrosion that can take place in certain mediums when operating in the 800-1200°F (427-649°C) temperature range.

321 Stainless Steel

Chromium 17-20%, Nickel 9-13%, Iron balance. Modified with the addition of Titanium to prevent carbide precipitation and resulting intergranular corrosion that can take place in certain mediums when operating in the 800-1200°F (427-649°C) temperature range.

Copper

Standard Copper Alloy A low temperature, inexpensive material used mainly for clean water heating. Maximum Sheath Temperature: 350°F / 177°C

Copper

Standard Copper Alloy A low temperature, inexpensive material used mainly for clean water heating. Maximum Sheath Temperature: 350°F / 177°C

Steel

Low Carbon Used for high to low viscosity oils, asphalt, tar, wax, molten salt, heat transfer liquid media and other compatible solutions.

Steel

Low Carbon Used for high to low viscosity oils, asphalt, tar, wax, molten salt, heat transfer liquid media and other compatible solutions.

Incoloy 825

Nickel 38-46%, Chromium 19.5-23.5%, Molybdenum 2.5-3.5%, Iron balance Available for a limited number of diameters. Consult Tempco for more information.

Incoloy 825

Nickel 38-46%, Chromium 19.5-23.5%, Molybdenum 2.5-3.5%, Iron balance Available for a limited number of diameters. Consult Tempco for more information.

Mounting Options

No options available for this section based on your selections

Round Mounting Flange

Standard ASTM Pressure-Rated Flange Sizes: 3, 4, 5, 6, 8, 10, 12, 14

Round Mounting Flange

Standard ASTM Pressure-Rated Flange Sizes: 3, 4, 5, 6, 8, 10, 12, 14

Square/Rectangular Mounting Flange

Custom Manufactured to meet application needs.

Flange Materials

No options available for this section based on your selections

Incoloy 800 Flange

A Nickel (30-35%), Chromium (19-23%), Iron alloy. The high nickel content of this alloy contributes to its resistance to scaling and corrosion. Used in air heating (also see Incoloy® 840) and immersion heating of potable water and other liquids that are not corrosive to an Incoloy® 800 sheath.

Incoloy 800 Flange

A Nickel (30-35%), Chromium (19-23%), Iron alloy. The high nickel content of this alloy contributes to its resistance to scaling and corrosion. Used in air heating (also see Incoloy® 840) and immersion heating of potable water and other liquids that are not corrosive to an Incoloy® 800 sheath.

304 SS Flange

A Chromium (18-20%), Nickel (8-11%), Iron Alloy used in the food industry, sterilizing solutions, air heating and many organic and inorganic chemicals.

304 SS Flange

A Chromium (18-20%), Nickel (8-11%), Iron Alloy used in the food industry, sterilizing solutions, air heating and many organic and inorganic chemicals.

304L SS Flange

A Chromium (18-20%), Nickel (8-11%), Low Carbon Iron Alloy used in the food industry, sterilizing solutions, air heating and many organic and inorganic chemicals.

304L SS Flange

A Chromium (18-20%), Nickel (8-11%), Low Carbon Iron Alloy used in the food industry, sterilizing solutions, air heating and many organic and inorganic chemicals.

316L SS Flange

A Chromium (16-18%), Nickel (11-14%), Low Carbon Iron Alloy with Molybdenum (2-3%) added to improve corrosion resistance in certain environments, especially those that would tend to cause pitting due to the presence of chlorides. Applications include deionized water.

316L SS Flange

A Chromium (16-18%), Nickel (11-14%), Low Carbon Iron Alloy with Molybdenum (2-3%) added to improve corrosion resistance in certain environments, especially those that would tend to cause pitting due to the presence of chlorides. Applications include deionized water.

Steel Flange

Low Carbon Steel: Applications include fluid heat transfer media, tar, high to low viscosity petroleum oils, asphalt, wax, molten salt, and other solutions not corrosive to a steel sheath.

Steel Flange

Low Carbon Steel: Applications include fluid heat transfer media, tar, high to low viscosity petroleum oils, asphalt, wax, molten salt, and other solutions not corrosive to a steel sheath.

Request Other Flange Material

If your filter selections do not return your desired results from our standard configurations, please continue to select your Specifications. When you are finished, save your selections in the Wish List (using the button at the right of this page) and follow the steps to submit them to Tempco.

Request Other Flange Material

If your filter selections do not return your desired results from our standard configurations, please continue to select your Specifications. When you are finished, save your selections in the Wish List (using the button at the right of this page) and follow the steps to submit them to Tempco.

Electrical Terminations

No options available for this section based on your selections

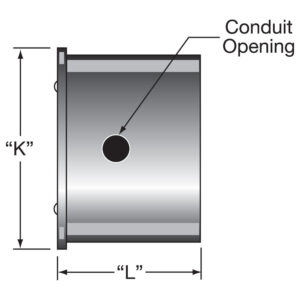

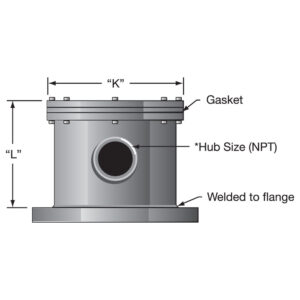

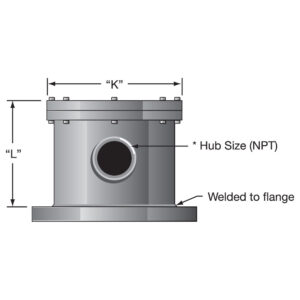

Type 1N Terminal Box

NEMA 1 rating For heaters having no thermostat Supplied with all Preconfigured and Stock Heaters All flange sizes See Learn More for flange sizes and measurements

Type 1N Terminal Box

NEMA 1 rating For heaters having no thermostat Supplied with all Preconfigured and Stock Heaters All flange sizes See Learn More for flange sizes and measurements

| Flange Size | “K” | “L” | Conduit Opening | ||

|---|---|---|---|---|---|

| in | mm | in | mm | ||

| 3 | 4-1/8 | 105 | 3-1/16 | 78 | 1-1/8 |

| 4 | 6 | 152 | 4 | 102 | 1-1/8 |

| 5 | 6-3/8 | 162 | 4 | 102 | 1-1/8 |

| 6 | 7-13/16 | 198 | 5-3/8 | 137 | 1-1/8 |

| 8 | 9-7/8 | 251 | 5-3/8 | 137 | 1-3/8 |

| 10 | 11-3/4 | 298 | 6 | 152 | 1-3/4 |

| 12 | 13-3/4 | 349 | 6 | 152 | 1-3/4 |

| 14 | 15-1/4 | 387 | 6 | 152 | 1-3/4 |

Scroll for more

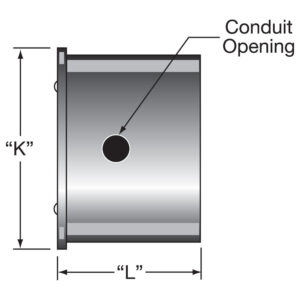

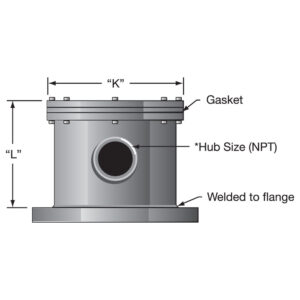

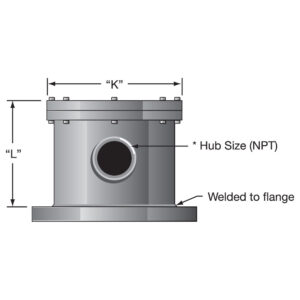

Type 1T Terminal Box

NEMA 1 rating For heaters with thermostat Supplied with all Preconfigured and Stock Heaters All flange sizes See Learn More for flange sizes and measurements

Type 1T Terminal Box

NEMA 1 rating For heaters with thermostat Supplied with all Preconfigured and Stock Heaters All flange sizes See Learn More for flange sizes and measurements

| Flange Size | “K” | “L” | Conduit Opening | ||

|---|---|---|---|---|---|

| in | mm | in | mm | ||

| 3 | 4-1/8 | 105 | 6 | 152 | 1-1/8 |

| 4 | 6 | 152 | 6 | 152 | 1-1/8 |

| 5 | 6-5/8 | 168 | 6 | 152 | 1-1/8 |

| 6 | 7-13/16 | 198 | 6 | 152 | 1-1/8 |

| 8 | 9-7/8 | 251 | 6 | 152 | 1-3/8 |

| 10 | CALL TEMPCO | ||||

| 12 | |||||

| 14 | |||||

Scroll for more

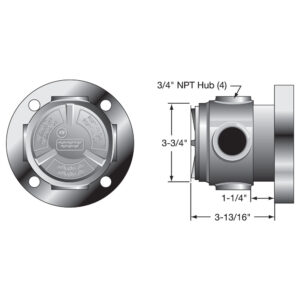

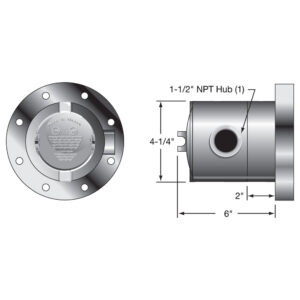

Type 2N Terminal Box

NEMA 4 rating For heaters having no thermostat 3 inch flanges Requires the use of the cover gasket

Type 2N Terminal Box

NEMA 4 rating For heaters having no thermostat 3 inch flanges Requires the use of the cover gasket

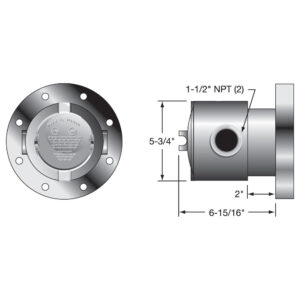

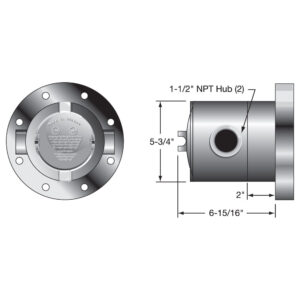

Type 2T Terminal Box

NEMA 4 rating For heaters with thermostat 3 inch flanges Requires the use of the cover gasket

Type 2T Terminal Box

NEMA 4 rating For heaters with thermostat 3 inch flanges Requires the use of the cover gasket

Type 3N Terminal Box

NEMA 4 rating For heaters having no thermostat 4 and 5 inch flanges Requires the use of the cover gasket

Type 3N Terminal Box

NEMA 4 rating For heaters having no thermostat 4 and 5 inch flanges Requires the use of the cover gasket

Type 3T Terminal Box

NEMA 4 rating For heaters with thermostat 4 and 5 inch flanges Requires the use of the cover gasket

Type 3T Terminal Box

NEMA 4 rating For heaters with thermostat 4 and 5 inch flanges Requires the use of the cover gasket

Type 4N Terminal Box

NEMA 4 rating For heaters having no thermostat 6 through 14 inch flanges See Learn More for flange sizes and measurements

Type 4N Terminal Box

NEMA 4 rating For heaters having no thermostat 6 through 14 inch flanges See Learn More for flange sizes and measurements

| Flange Size | “K” | “L” | Conduit Opening | ||

|---|---|---|---|---|---|

| in | mm | in | mm | ||

| 6 | 8 | 203 | 6 | 152 | 2 |

| 8 | 10 | 254 | 6 | 152 | 2 |

| 10 | 13-3/4 | 349 | 6 | 152 | 2-1/2 |

| 12 | 15-5/8 | 397 | 6 | 152 | 2-1/2 |

| 14 | 17-1/4 | 438 | 6 | 152 | 2-1/2 |

Scroll for more

Type 4T Terminal Box

NEMA 4 rating For heaters with thermostat 6 through 14 inch flanges See Learn More for flange sizes and measurements

Type 4T Terminal Box

NEMA 4 rating For heaters with thermostat 6 through 14 inch flanges See Learn More for flange sizes and measurements

| Flange Size | “K” | “L” | Conduit Opening | ||

|---|---|---|---|---|---|

| in | mm | in | mm | ||

| 6 | 8 | 203 | 6 | 152 | 2 |

| 8 | 10 | 254 | 6 | 152 | 2 |

| 10 | 13-3/4 | 349 | 7-1/2 | 191 | 2-1/2 |

| 12 | 15-5/8 | 397 | 7-1/2 | 191 | 2-1/2 |

| 14 | 17-1/4 | 438 | 7-1/2 | 191 | 2-1/2 |

Scroll for more

Type 5N Terminal Box

NEMA 7 rating For heaters having no thermostat 6 through 14 inch flanges See Learn More for flange sizes and measurements.

Type 5N Terminal Box

NEMA 7 rating For heaters having no thermostat 6 through 14 inch flanges See Learn More for flange sizes and measurements.

| Flange Size | “K” | “L” | Conduit Opening | ||

|---|---|---|---|---|---|

| in | mm | in | mm | ||

| 6 | 9-3/8 | 203 | 6 | 152 | 2 |

| 8 | 11-1/2 | 254 | 6 | 152 | 2 |

| 10 | 13-3/4 | 349 | 6 | 152 | 2-1/2 |

| 12 | 13-5/8 | 397 | 6 | 152 | 2-1/2 |

| 14 | 17-1/2 | 438 | 6 | 152 | 2-1/2 |

Scroll for more

Type 5T Terminal Box

NEMA 7 housing For heaters with thermostat 6 through 14 inch flanges See Learn More for flange sizes and measurements

Type 5T Terminal Box

NEMA 7 housing For heaters with thermostat 6 through 14 inch flanges See Learn More for flange sizes and measurements

| Flange Size | “K” | “L” | Conduit Opening | ||

|---|---|---|---|---|---|

| in | mm | in | mm | ||

| 6 | 9-3/8 | 203 | 7-1/2 | 191 | 2 |

| 8 | 11-1/2 | 254 | 7-1/2 | 191 | 2 |

| 10 | 13-3/4 | 349 | 7-1/2 | 191 | 2-1/2 |

| 12 | 13-5/8 | 397 | 7-1/2 | 191 | 2-1/2 |

| 14 | 17-1/2 | 438 | 7-1/2 | 191 | 2-1/2 |

Scroll for more

Request Other Electrical Terminations

If your filter selections do not return your desired results from our standard configurations, please continue to Refine Results for your specifications. When you are finished, save your selections with the Save Results for Quote button (at the right of this page) and choose Request for Quote for further assistance.

Request Other Electrical Terminations

If your filter selections do not return your desired results from our standard configurations, please continue to Refine Results for your specifications. When you are finished, save your selections with the Save Results for Quote button (at the right of this page) and choose Request for Quote for further assistance.

Thermostats

No options available for this section based on your selections

SPST Thermostat

Single Pole – Single Throw Thermostats: Style A, Style D, Style F

Request Other Thermostat

If your filter selections do not return your desired results from our standard configurations, please continue to select your Specifications. When you are finished, save your selections in the Wish List (using the button at the right of this page) and follow the steps to submit them to Tempco.

Request Other Thermostat

If your filter selections do not return your desired results from our standard configurations, please continue to select your Specifications. When you are finished, save your selections in the Wish List (using the button at the right of this page) and follow the steps to submit them to Tempco.

Thermostat Options

No options available for this section based on your selections

Stuffing Box Assembly

The Stuffing Box Assembly is used to seal the thermostat capillary when the sensing bulb (3/8″ max. OD) is immersed directly in a liquid rather than in a thermowell. The Stuffing Box consists of six slotted washers used to compress a graphite packing into a 3/8″ NPT male pipe thread fitting. Assembly Instructions Feed sensing bulb through hole in upper and lower fitting. Insert washers and packing into top cavity of lower fitting. Upper fitting then screws into lower fitting, creating the seal. Part Number: TST-109-101

Stuffing Box Assembly

The Stuffing Box Assembly is used to seal the thermostat capillary when the sensing bulb (3/8″ max. OD) is immersed directly in a liquid rather than in a thermowell. The Stuffing Box consists of six slotted washers used to compress a graphite packing into a 3/8″ NPT male pipe thread fitting. Assembly Instructions Feed sensing bulb through hole in upper and lower fitting. Insert washers and packing into top cavity of lower fitting. Upper fitting then screws into lower fitting, creating the seal. Part Number: TST-109-101

Thermowells

Stainless Steel or Plain Steel: Thermowells provide protection for bulb and capillary sensors. They are supplied with a 1/2″ NPT male thread for mounting and a 3/8″ NPT internal thread that can be used with the stuffing box assembly to secure the capillary to the well. ID: 0.50″, OD: 0.56

Thermowells

Stainless Steel or Plain Steel: Thermowells provide protection for bulb and capillary sensors. They are supplied with a 1/2″ NPT male thread for mounting and a 3/8″ NPT internal thread that can be used with the stuffing box assembly to secure the capillary to the well. ID: 0.50″, OD: 0.56

Heater Options

No options available for this section based on your selections

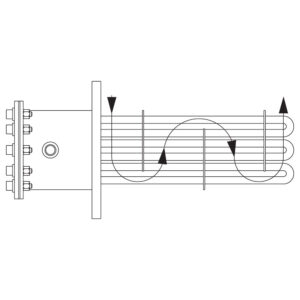

Flow Control Baffles

For flange heaters used in circulation tanks, to aid heat transfer by forcing the liquid or gas back and forth across the elements. Baffles can be custom designed and positioned for your application.

Flow Control Baffles

For flange heaters used in circulation tanks, to aid heat transfer by forcing the liquid or gas back and forth across the elements. Baffles can be custom designed and positioned for your application.

Terminal Housing Standoff

The electrical housing is separated from the flange by an air gap (six-inch standard) to lower the ambient temperature of the electrical wiring. This option is used on flanged immersion heaters where the flange temperature exceeds 482°F (250°C).

Terminal Housing Standoff

The electrical housing is separated from the flange by an air gap (six-inch standard) to lower the ambient temperature of the electrical wiring. This option is used on flanged immersion heaters where the flange temperature exceeds 482°F (250°C).