Tempco was approached by a well-recognized leader in the medical industry, specifically an original equipment manufacturer (OEM) in the sterilization and infection markets. Our collaboration began with a request to evaluate two of their popular autoclave benchtop models. This engagement set the stage for a series of strategic discussions to identify key testing criteria hoping to optimize performance and reduce costs.

Testing Criteria:

- Cold-start time reduction

- Simplification of current heater design(s)

- Energy efficiency

- Lower heater costs

- Maintain established heater power requirement for autoclave units

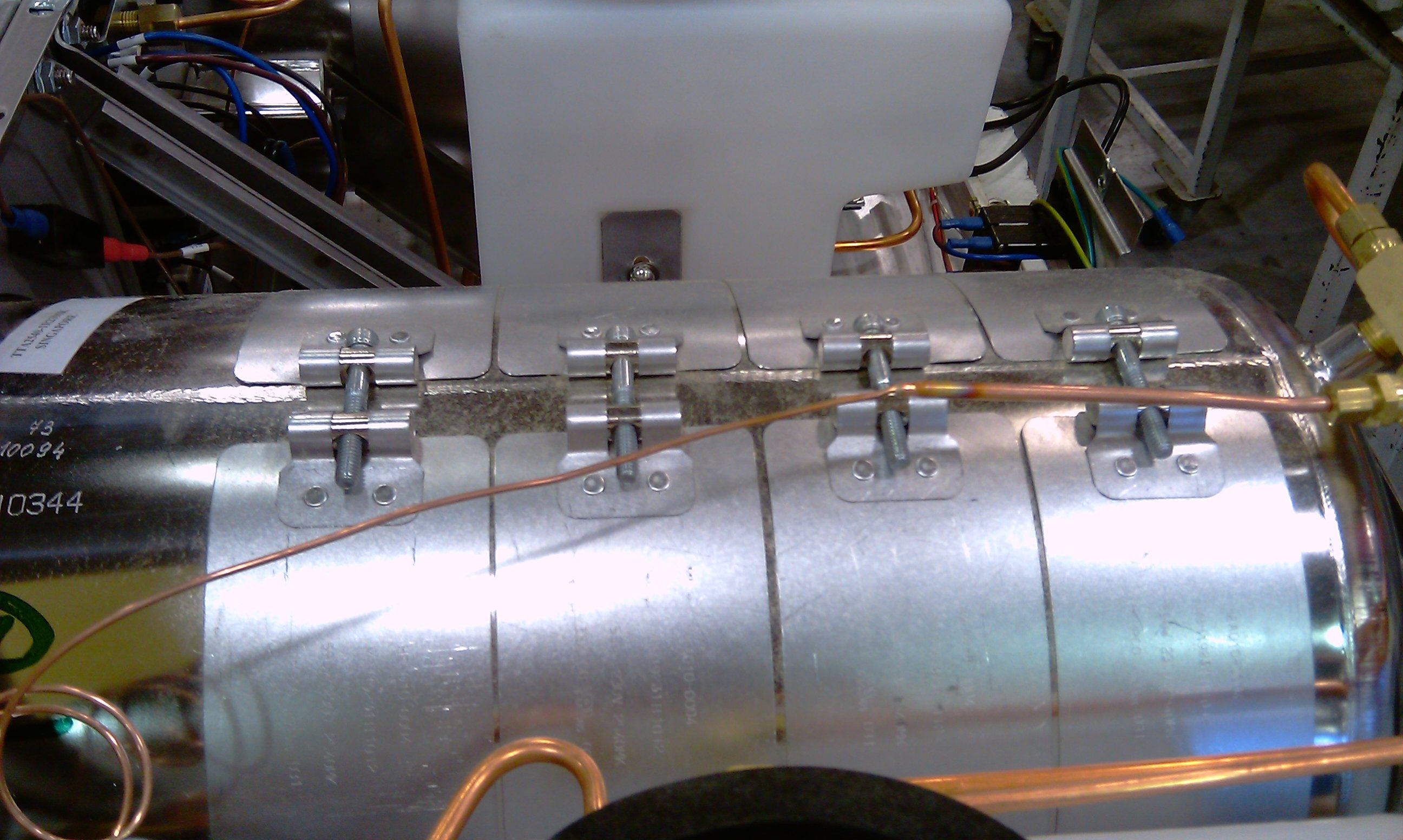

The autoclave units were shipped to our facilities and placed in our lab where our product engineer, Filip M., conducted a thorough review and testing. These autoclaves utilized Tempco’s Duraband® Heaters, commonly known as mica band heaters, which are designed for efficient heat transfer in various configurations. They are usually fashioned in various clad materials and conform to various cylinder sizes. These band heaters are secured on the outside of the chamber or business end of the autoclave to perform the function of heat transfer to the chamber’s interior.

Design Variations for Testing

To maximize the potential for cost savings and efficiency, we evaluated several design variations on the Autoclaves Chamber:

- Two different sheath materials were used to test heater thermal conductivity

- Variations in heater sizes were considered for serviceability and cost efficiencies

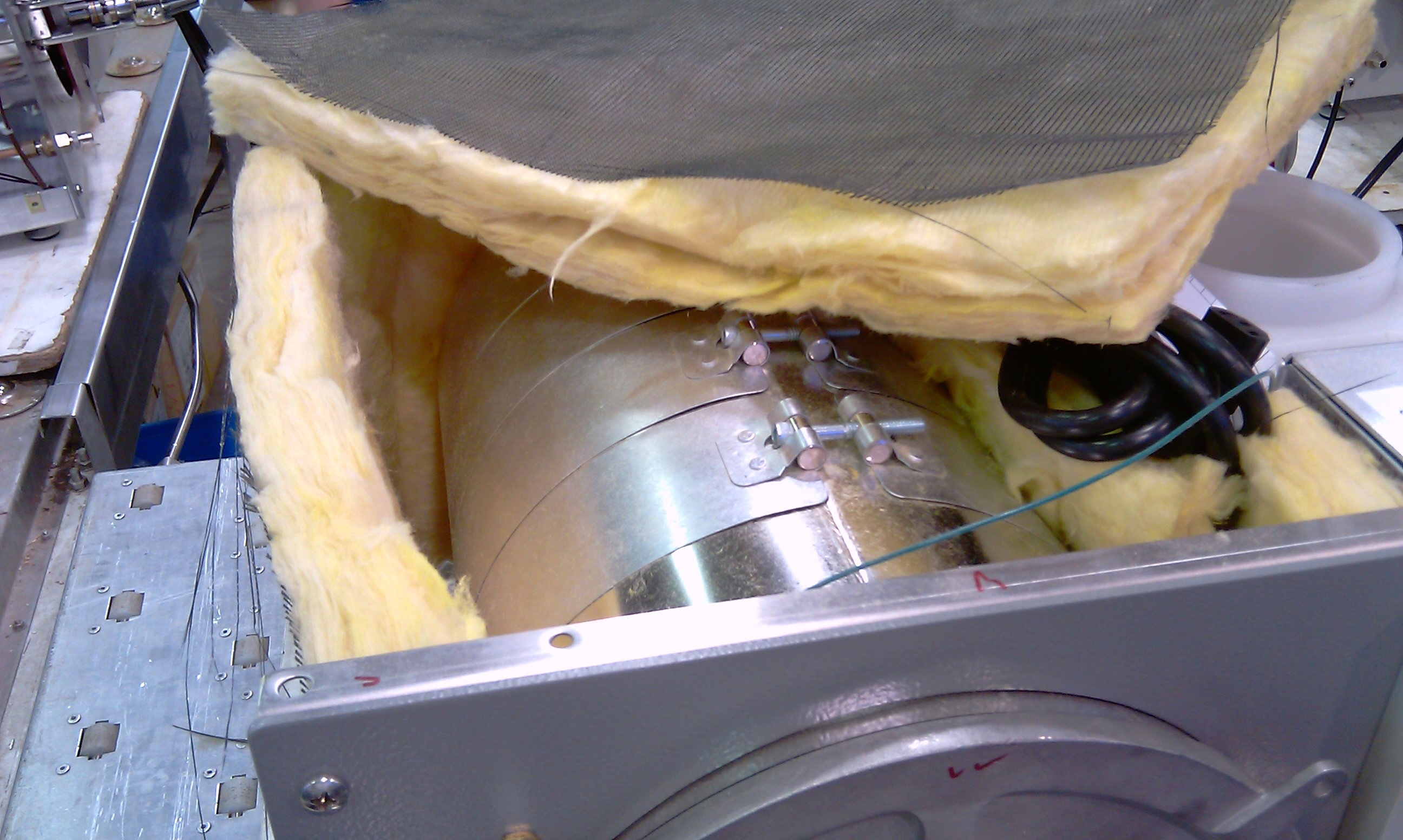

- Insulation materials were examined to cover the exterior of chamber

- Heater prototype units were developed to explore covering or heating other areas of chamber

Key Findings

We were able to draw several conclusions through testing.

- Tempco was able to show a reduction in the cost of the heaters by changing the sheath material to aluminized steel.

- Serviceability could not be improved, and energy efficiency was not positively affected with the addition of insulation material.

- Tempco’s theory that cold-start time could not be reduced without raising the power of the original heaters was confirmed.

- The prototypes did not offer any advantages when heating other segments of the chamber.

Testing Autoclaves with Additional Insulation

While not all results were favorable, we were able to answer critical questions regarding performance and efficiency. Most importantly, we successfully demonstrated a significant reduction in heater costs by switching the sheath material to aluminized steel. Notably, this change did not compromise thermal conductivity, maintaining the application’s performance.

In the end, Tempco continued to provide a reliable heat source in the form of our mica-insluated Duraband Heaters to our customer.Tempco remains committed to providing reliable heating solutions. By leveraging our extensive testing and engineering expertise, we were able to offer our OEM partner a cost-effective alternative while ensuring the continued performance of our mica-insulated Duraband Heaters. For other OEMs facing similar challenges, Tempco stands ready to deliver tailored heating solutions that enhance efficiency and reduce operational costs. Let us help you find the optimal solution for your next project.