A company that services and rebuilds extruders for the plastics industry approached Tempco seeking help to convert an existing extruder from a liquid-cooled system to a more energy efficient air-cooled system with finned cast-in heaters and stainless-steel shrouds. The challenge for this conversion was that one of the heat/cool zones had an existing butane line coming out from the center of the zone at the top of the barrel. The customer wanted a custom shroud that could be mounted to the barrel without having to disconnect the butane line from the barrel.

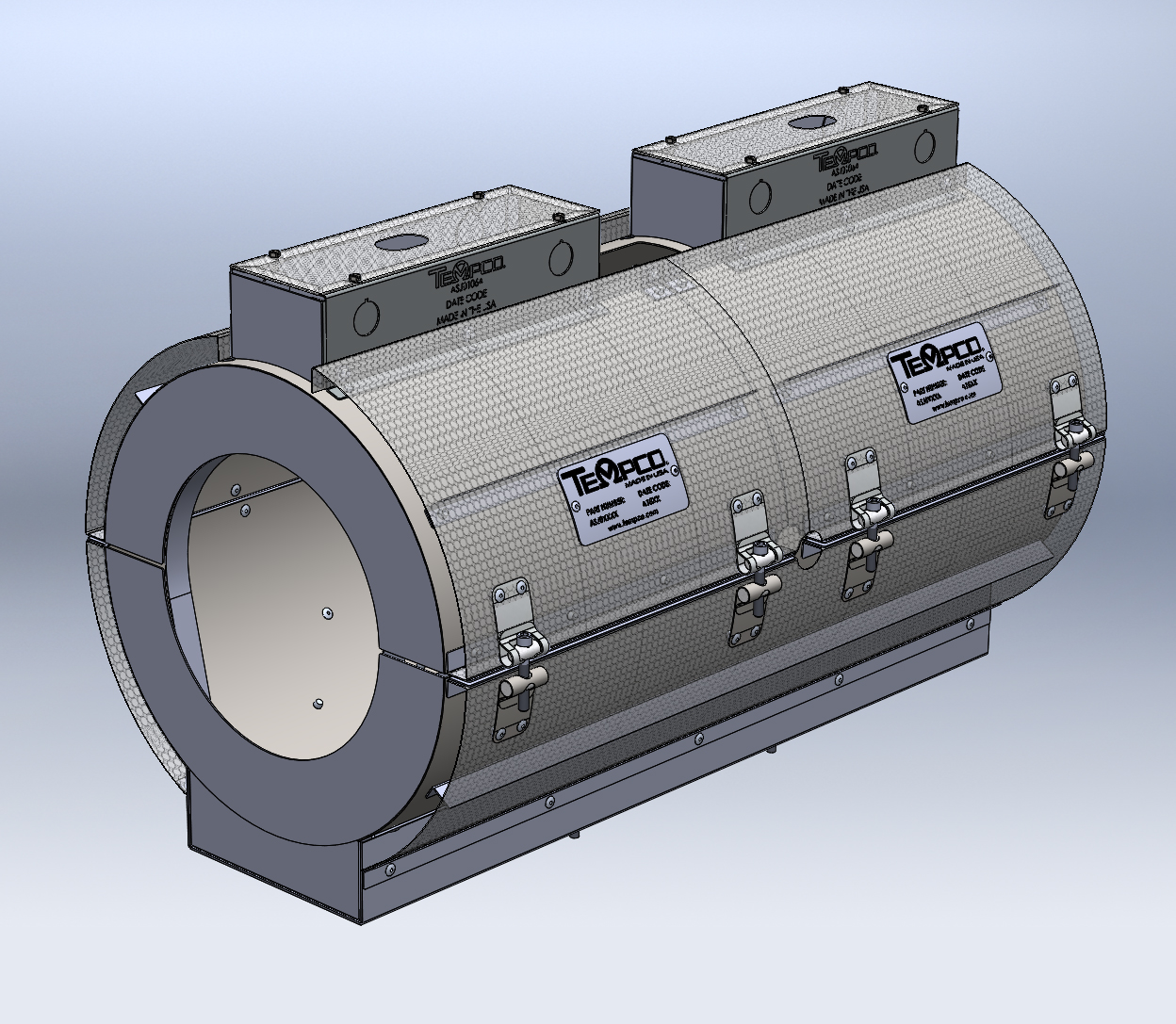

Tempco worked closely with our customer and came up with a viable solution. We agreed that a custom 3-piece, Cool TO-THE Touch shroud would be the best solution for that zone. The shroud was designed with the top half split down the middle and cut-outs on each half that fit around the butane line. The customer was able to mount the shroud to the barrel without having to disconnect the existing butane line making installation quick and easy, thus saving time and money.

Once the design was approved by our customer, TEMPCO was able to build and ship the new air-cooled system within 30 days.