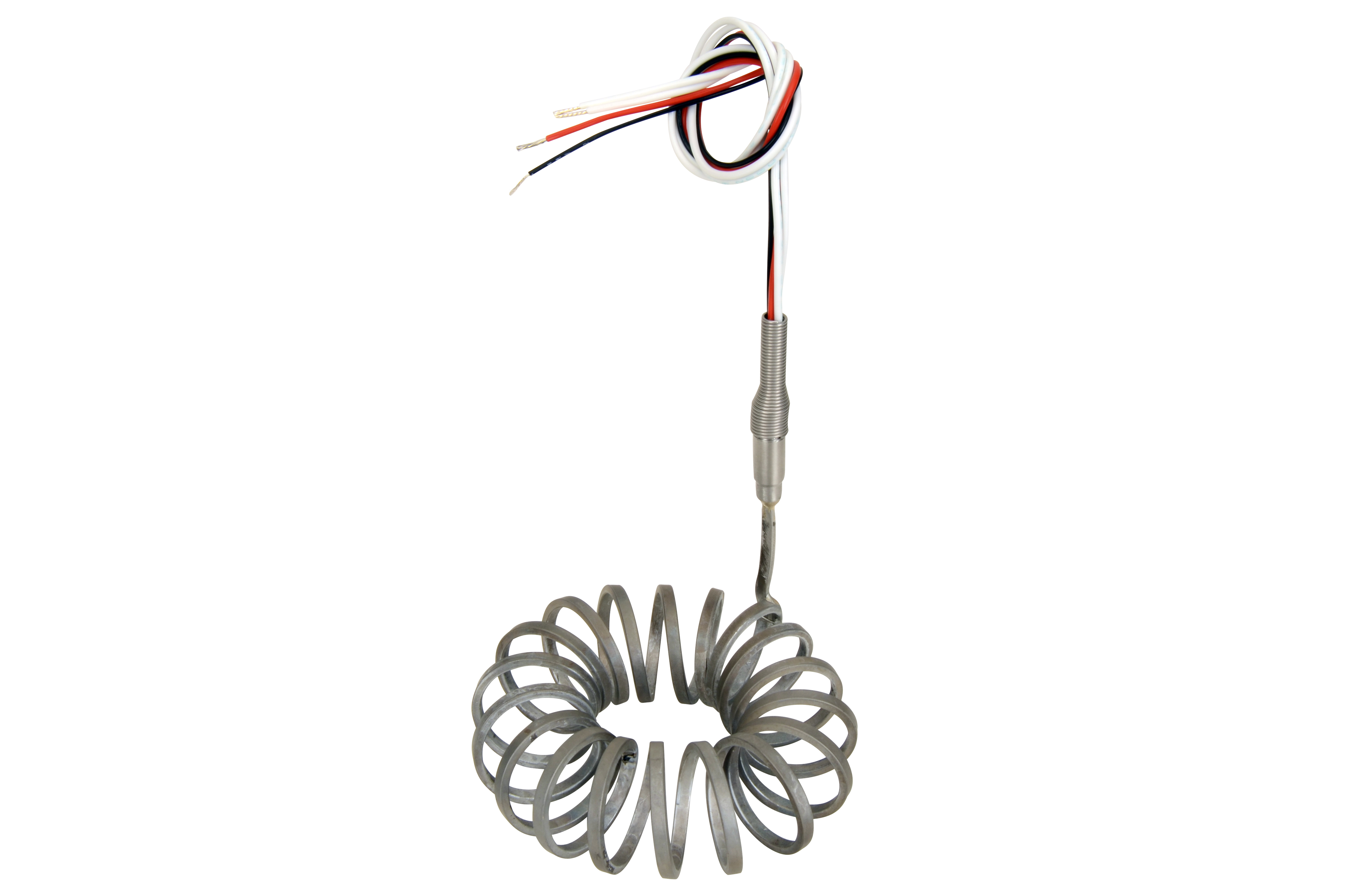

The Superior Coil Heater Design with Built-In Thermocouple

Common Applications

- Air heating

- Blow Molding

- Custom Die Applications

- Extrusion

- Freeze Protection

- Heat Trace

- Heating in a vacuum environment

- Hot Runner Systems

- Injection Runnerless Molding Bushings

- Internally Heated Injection Machine Nozzles

- Laminating and printing presses

- Mass Spectrometry

- Metal Forming Dies and Punches

- Package Sealing and Cutting Bars

- Restaurant/Food Processing Equipment

- Scientific Instrumentation

- Semiconductor manufacturing:

- wafer processing

- pedestal heating

- shower head heating

- Textile manufacturing

- Thermoforming

Design Features

- Temperatures up to 1800°F (982°C)

- Precise temperature control

- Choice of lead orientation

- Built-in type J or K Thermocouple

- Round, square and rectangular cable

- Rugged, durable construction

- Unheated straight section

- Fast response time

- Choice of lead protection

- Longer heater life

- Higher watt densities

- Custom made to customer specifications

A Revolutionary Concept in Heater Design

Tempco Mightyband heaters opened new frontiers and revolutionized the plastic injection runnerless molding industry since their introduction by Tempco in 1977. They provided the manufacturers of this type of equipment with a new and more effective heating element concept. These coil heaters allowed them to design and manufacture new, improved, and more efficient runnerless molding systems with the capabilities required to meet the ever-increasing demand for processing engineering resins and high production output requirements of today’s industrial and consumer markets.

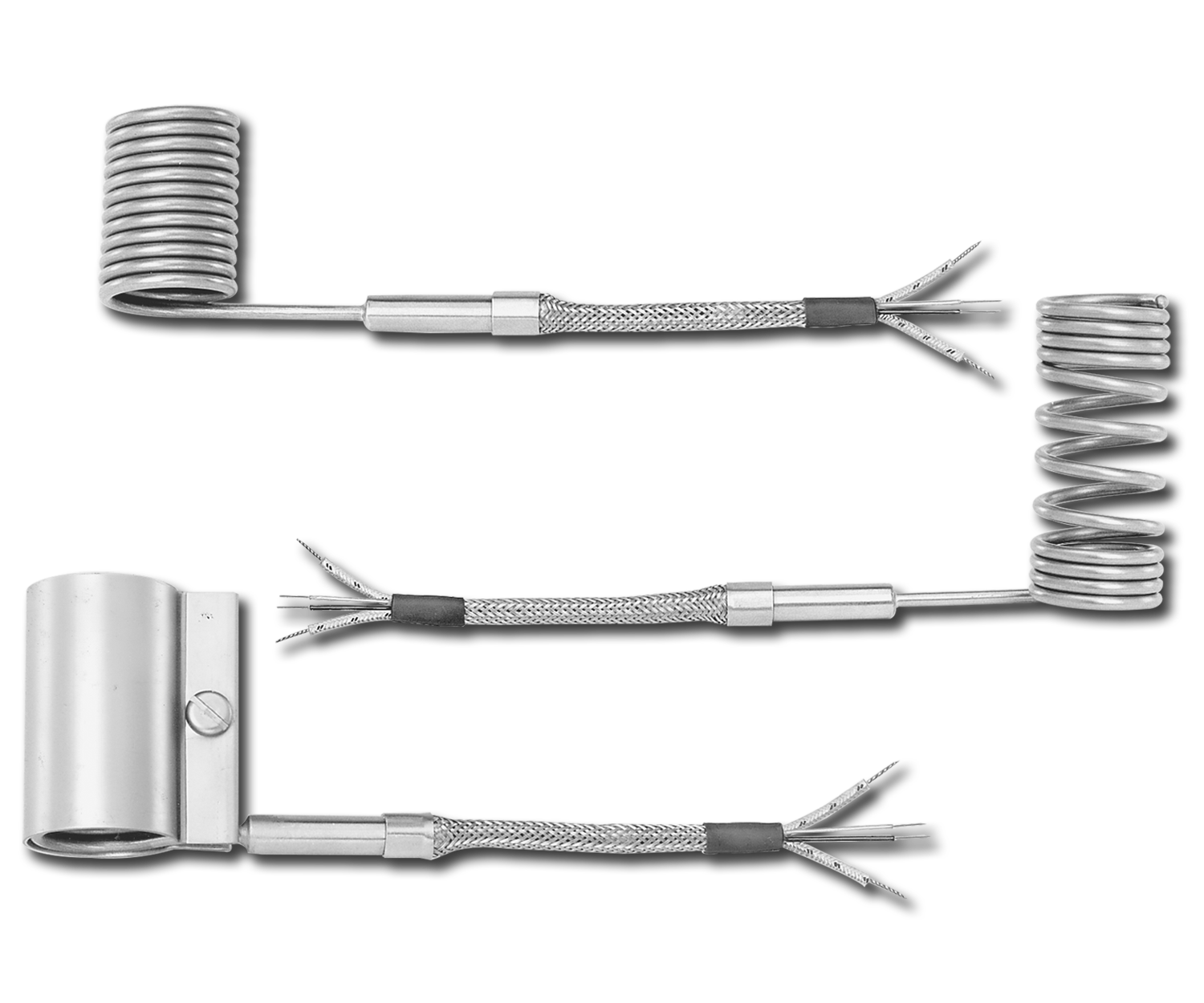

Three Cable Types

Round Cable

Heating element is embedded in MgO insulation inside a round tube.

Square Cable

Rectangular Cable

Heating element is embedded in MgO insulation inside a square or rectangular tube. Because of the flat surface, in some applications square/rectangular cable allows better heat conduction and a faster start-up time.

Construction Characteristics

The Heating Element

The heating source for the Mightyband Coil Heater is a resistance wire in straight form or wound into a miniature helical coil. Selecting the best-suited resistance wire configuration is predetermined by an engineering formula applied to the specific heater design.

On Mightyband heaters where wire wound resistance coils are used, the tail end of the heater cable is usually unheated. Optional unheated or cooler tail sections are available on straight resistance wire heater designs. Consult Tempco with your specific requirements.

The swaging and drawing process involved in manufacturing the heater cable for Mightyband heaters compacts the ceramic insulators that house the heating element and thermocouple wire into a solid mass, producing a rugged and durable heater cable, providing excellent thermal conductivity and dielectric strength and quick thermocouple response.

The Temperature Sensor

The design and manufacturing concept of Tempco’s Mightyband Heaters incorporates a built-in thermocouple with a grounded junction terminating at the end of the cable opposite to the lead end. In some heaters, the thermocouple junction can be terminated anywhere within the coil section.

The built-in thermocouple and the overall low mass construction provide quick response for positive temperature control. Incorporating the thermocouple into the heater construction eliminates the need for separate thermocouples, which have proven to be expensive, fragile and impractical.

Standard Type J thermocouple with 304 stainless steel heater sheath is recommended for temperatures up to 1500°F (815°C). An optional Type K thermocouple with Inconel® 600 heater sheath for temperatures up to 1800°F (982°C) is available upon request. In some applications, the built-in thermocouple may not be required. In this case, it can be omitted from the heater cable.

Custom Coil and Cable Heater Designs