The safety and the economical operation of pressurized water nuclear reactors are dependent, in large part, on the fuel rod behavior. Nuclear research centers often use high-density, electric-resistive heaters that replicate these fuel rods to investigate their thermodynamic behaviors such as:

- heat flux density

- associated heat flux density distribution

- heat capacity.

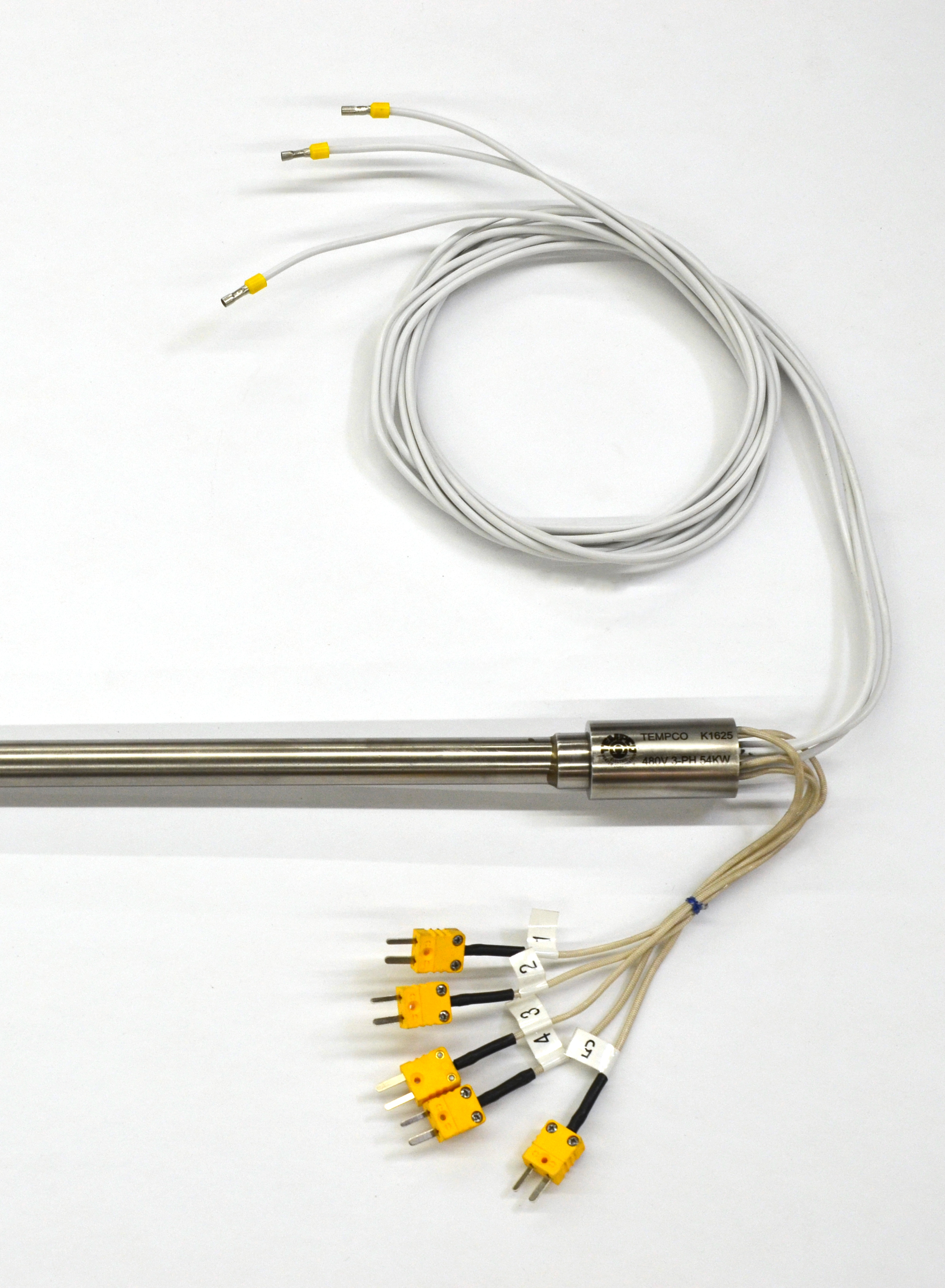

Tempco was approached by a renowned university research center to manufacture a heater for use as a simulator for a nuclear fuel rod in their reactor studies. They requested an electric cartridge-type heater with a watt density of 200 watts/in² (310 KW/m²) and internal sensors. To meet the application requirements, Tempco successfully designed and manufactured a cable heater with these specifications:

- 138″ long

- 3/4″ diameter

- 54KW

- 480V 3-phase power

- five internal type “K” thermocouples

- 316SS sheath material.

The five simulator thermocouples with isolated junctions are distributed along the heated length of the electric heater. They are positioned so that they have intimate contact with the inner wall of the 316SS sheath for accurate temperature reading of the heater sheath and rapid response time. The most significant and unique feature of this high-performance heater is that the watt density of the internal resistance elements is lower than the watt density of the heater sheath. It was designed this way to maximize and extend the longevity of the heater.