The Cartridge Heater is a reliable electric heating element used across many industries as a localized heat source within industrial processing equipment. One such industry is the Food and Beverage Industry which is in constant need of precise heating elements for all of its activities such as:

- Preparation

- Processing

- Preservation

- Packaging

Tempco cartridge heaters are designed with the unique challenges of food and beverage processing in mind. With custom options and a range of performance features, these heaters can handle the rigorous requirements of food-related applications. For instance, a Tempco cartridge heater can be built with watt densities as high as 300 W/square inch and reach working temperatures up to 1400°F.

Tempco offers a variety of options with our cartridge heater design features:

- Electrical terminations

- Termination options

- Sheath options

- Temperature sensor options

- Power variations

Perhaps the most important design features for food and beverage processing are the available sheath materials and options. Tempco offers several premium sheath materials to ensure durability and protection in demanding environments.

Designed for Safety and Durability: Materials That Meet Food-Grade Standards

Besides our standard 321 Stainless Steel and Incoloy® 800 sheath materials, Tempco also offers 316L Stainless Steel, which is considered to be the best food-grade stainless steel. When combined with Passivation, a chemical process that removes surface contamination, and Electro-Polishing, a process that removes surface imperfections and contaminants, these materials offer excellent corrosion protection. These advanced treatments ensure that the heaters meet the high cleanliness standards required for food processing, particularly in applications where hygiene and safety are critical. In addition, Tempco manufactures our own standard and custom fittings for various mounting options and moisture resistant terminations that are also important within the industry.

Innovation and Experience You Can Trust: 50 Years of Heating Expertise

Innovation and Experience You Can Trust: 50 Years of Heating Expertise

With almost 50 years of experience in designing and manufacturing heating elements, Tempco has the knowledge to deliver high-performance heaters for any food and beverage application. Our expertise in custom heating solutions gets you the right product for your unique needs.

High-Performance Heating for Every Step of Food Processing

Tempco cartridge heaters are versatile and effective in various food and beverage applications. Here are just a few ways they power critical processes:

- Baking Equipment

- Beverage Carbonation

- Candy Making Equipment

- Coffee Makers

- Dairy Equipment

- Food Warmers

- Grills – igniting wood pellets

- Refrigeration Equipment

- Sealing Bars for Packaging Machines

- Smokers

- Water heating

Custom Cartridge Heaters for Food and Beverage Industry Applications

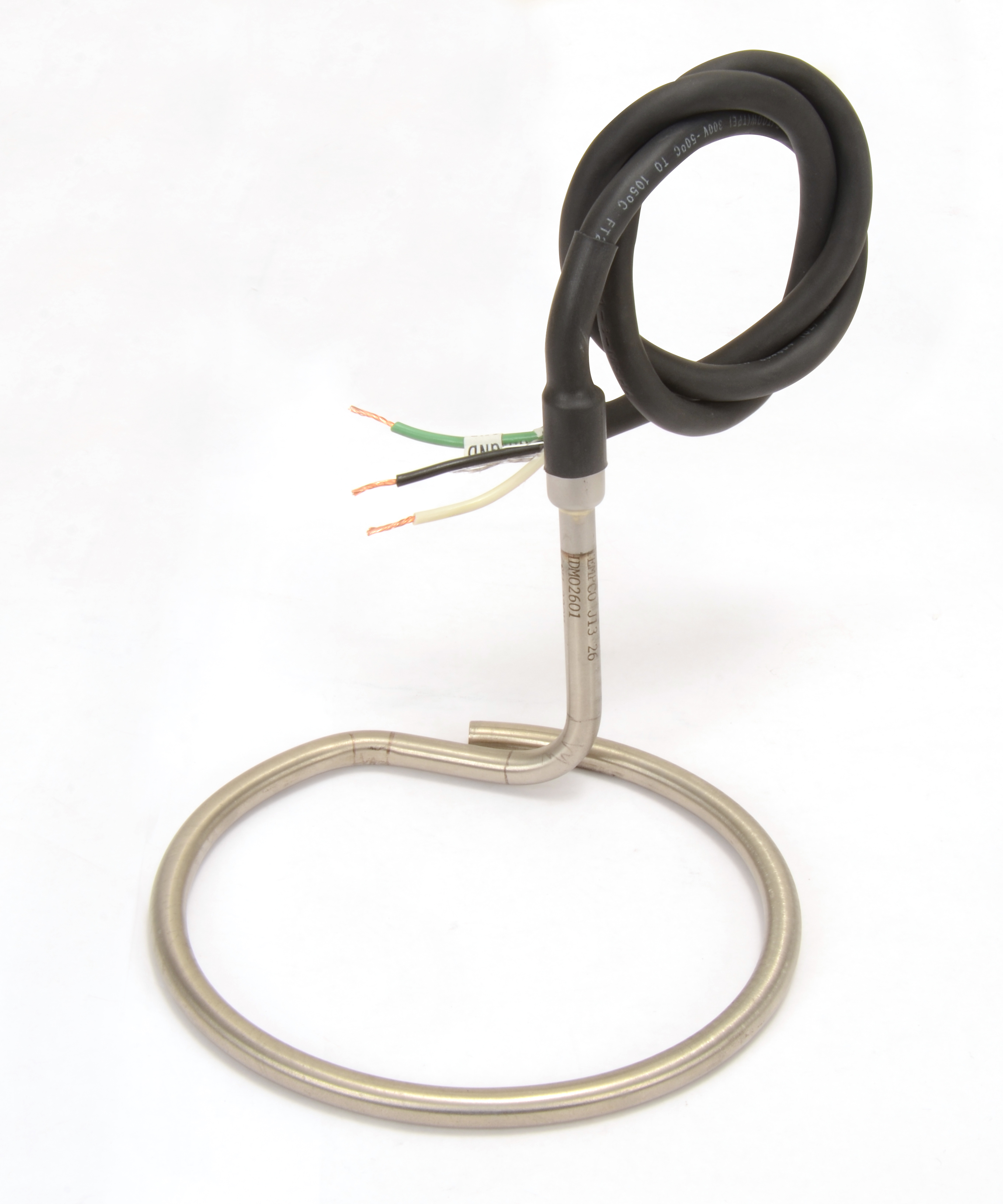

Formed High Density Cartridge Heater for Food Packaging Machinery

Design Features

- Cartridge heater formed into circular formation

- When a formed heater is required, a tubular element is usually the first choice. However, when the watt density is too high for a tubular heating element, a Tempco Hi-Density Cartridge Heater is a viable alternative.

- Moisture resistant seal and flexible SJO cord

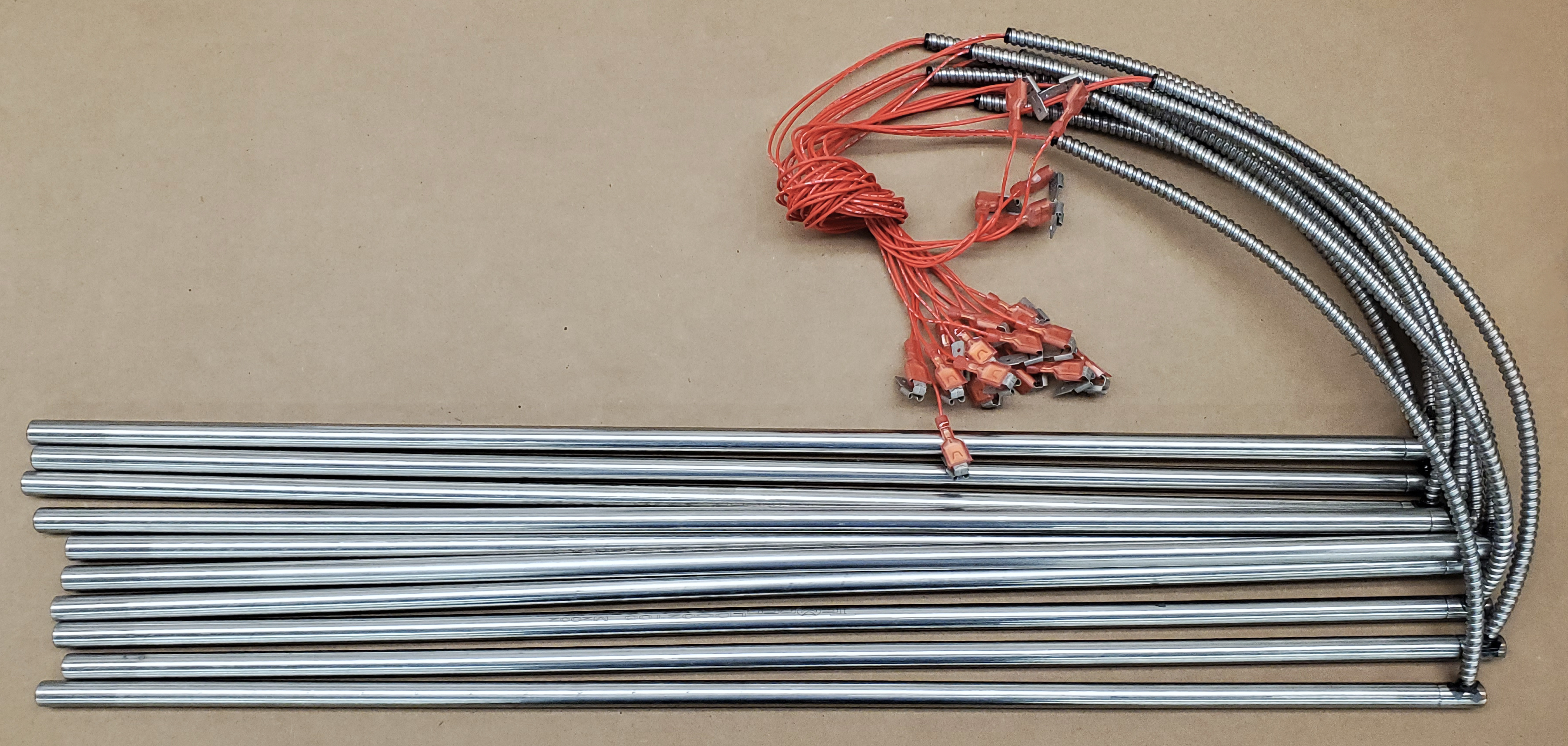

Cartridge Heaters used in Flour Tortilla Press

Design Features:

- Designed for high voltage use

- Electrical Termination is screw terminals to enable quick connection of the power cable

- Moisture resistant seal

- Mounting flange

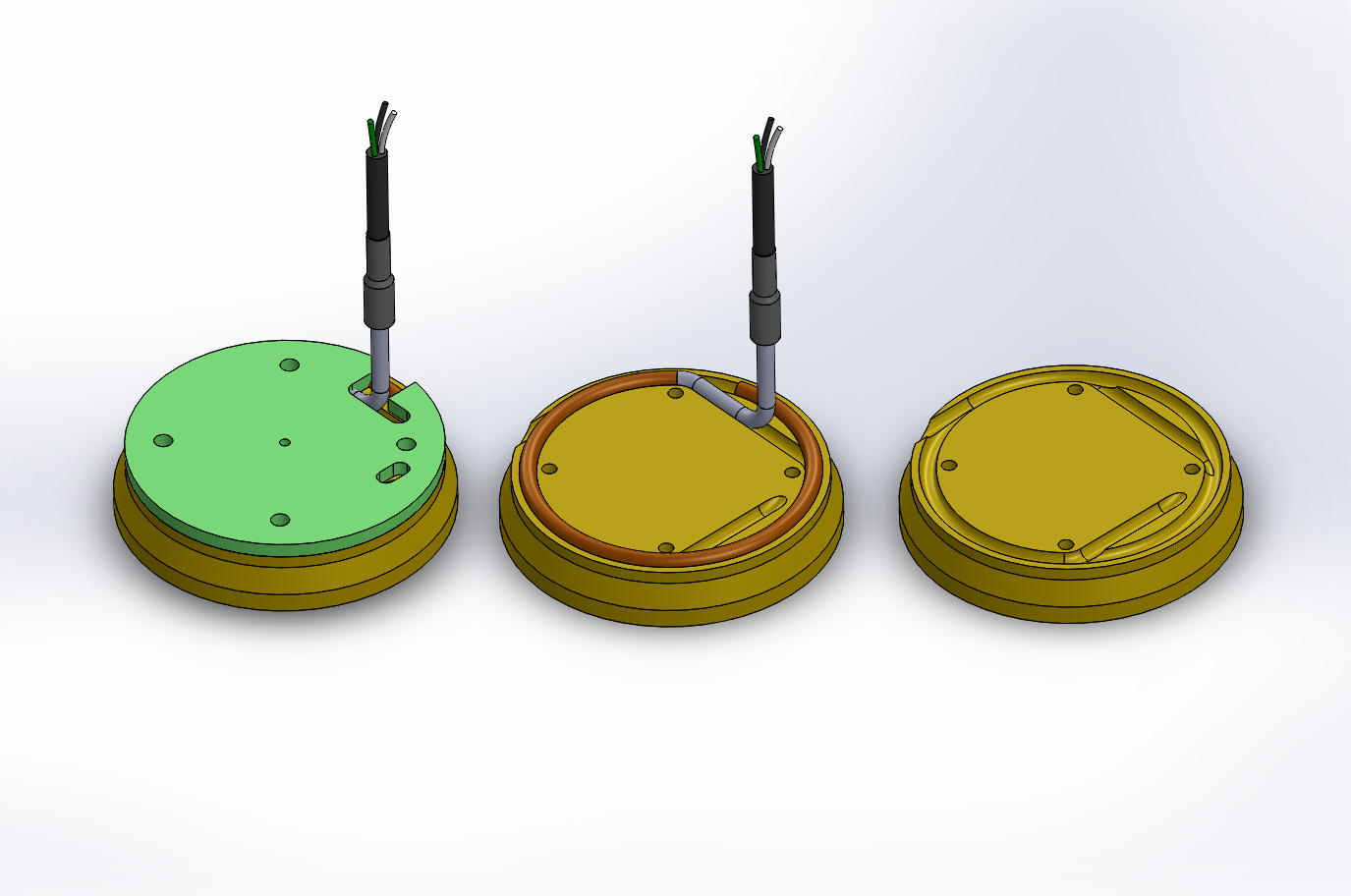

Self-controlled Low-Density Cartridge Heater for Film Wrapping Machine

Design Features:

- Uniform heat distribution across application

- Built-in thermostat allows for self-controlled temperature

- Quick disconnect electrical termination

- Stainless Steel cable for abrasion protection on electrical termination

High Density Cartridge Heater for Beverage Carbonation

Design Features:

- Custom, Tempco-made fitting for the mounting option

- Built-in thermostat allows for self-controlled temperature

- Moisture resistant seal

- SJO cord

Going Beyond Basic Heating: Get Custom Solutions

With our engineering expertise and unique Manufacturing capabilities, Tempco can address the challenges of original equipment manufacturers (OEM’s) and maintenance (MRO) applications within the food and beverage industry. In addition, we offer services that drastically reduce the normal delivery time. The Pronto service can be used for non-stock and custom manufactured heaters, while the Terminator service offers 1-3 day delivery on custom-terminated cartridge heater substrates. For a complete thermal loop, Tempco also manufactures Temperature Sensors and Temperature Control Products.

Helpful Links

Cartridge Heater Product Lines

Cartridge Heater Specifications and Tolerances

Sheath Material Selection Guide