An internationally known vendor in the food and beverage industry approached Tempco in need of circulation heaters. As conversations evolved between Tempco and the potential customer, we learned more about the application, including their intention to make the necessary process and temperature control panels themselves. After additional discussions they agreed to give us the panel specifications so we could quote the added value of building the panels for their application. We learned that we were in competition with several other heater manufacturers. Ultimately, Tempco won the project purchase order due to our extensive industry knowledge, accessibility, quick response time and straight-forward approach.

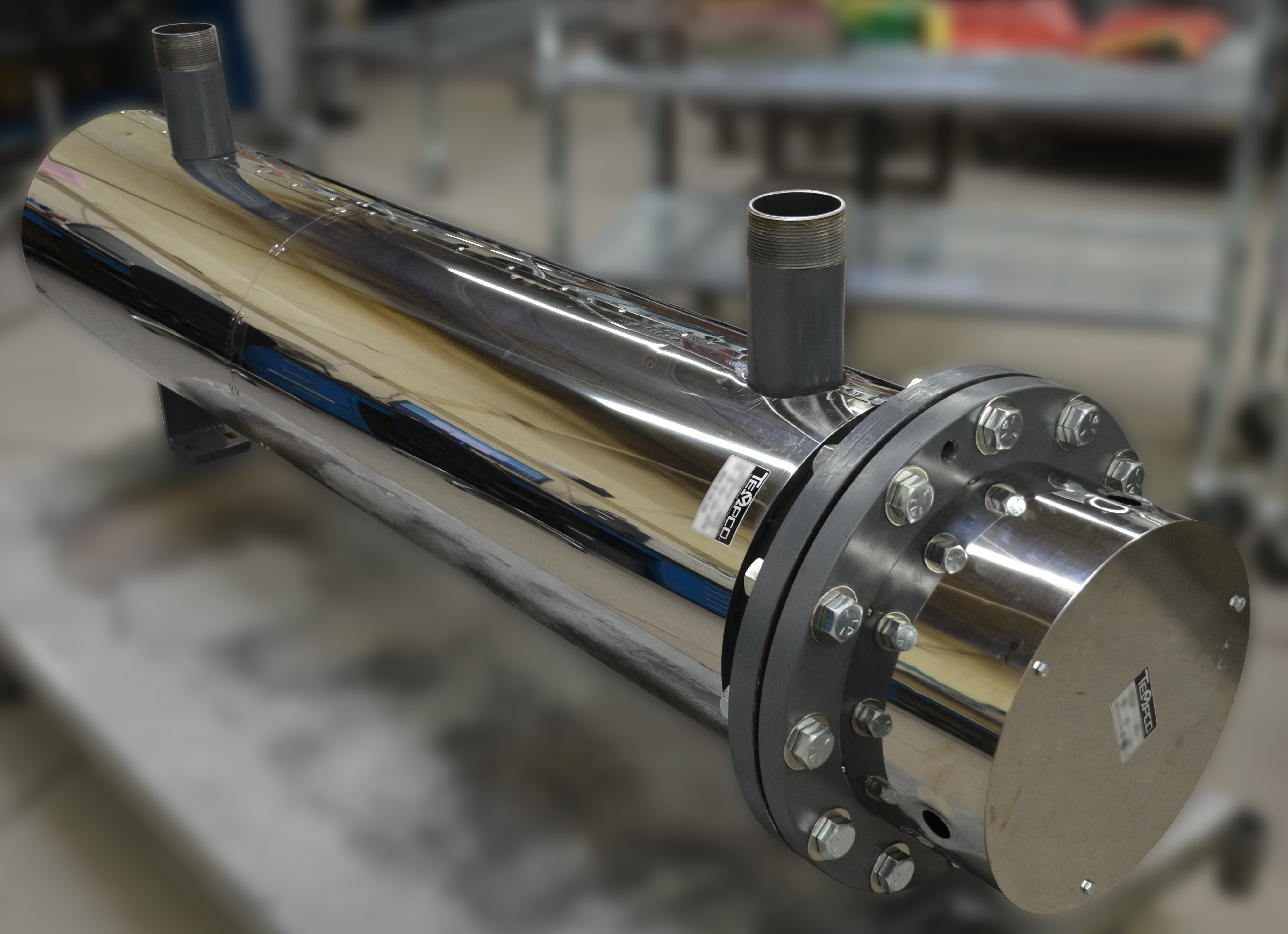

The application involved chilled propylene glycol being circulated through a food processing system. Once or twice a week the system needed to be cleaned and sterilized. To do this properly and safely, the temperature of the system had to be brought from 1°F up to 212°F. Over the course of several months the design of the circulation process heaters and the panels changed when there was room for improvement. The final process heater specifications were:

- 24 tubular heating elements

- 40 kilowatts

- 480 volts, 3-Phase

- 53.25” in length

- 8” 150 lb flange

- (2) hi-limit RTD temperature sensors

To properly manage the system and interface with the customer’s Programmable Logic Controller (PLC), Tempco designed and built four control panels in our 504A Panel Shop. They had the following specifications:

- 46”H x 24”W x 10.0”D NEMA 12 Enclosure

- 60A SCR Power controller, D Series

- Contactors

- Main power disconnect switch

- Controls On/Off switch and green indicator light

- TEC-9300 PID temperature controller

- TEC-910 High limit controller

- Red over temperature indicator light and manual reset button

- Fan & filter kit

From our engineering and sales departments to our accounting department to our production departments, Tempco worked seamlessly and tirelessly to provide our new customer with quality service and products.

Typical Control Panel Shown